The experiment was designed and completed in 2014 by Christian Lessmeier, Enge-Rosenblatt, Bayer, & Zimmer, University of Paderborn, Germany.

Data download link: https://mb.uni-paderborn.de/kat/forschung/datacenter/bearing-datacenter/ Name of the Institute and KAt-DataCenter link: Christian Lessmeier et al. Chair of Design and Drive Technology, University of Paderborn. For commercial use, please contact the author.

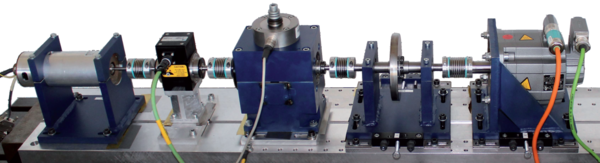

The test rig consists of several modules: an electric motor

- a torque-measurement shaft

- a rolling bearing test module

- a flywheel

- and a load motor

see Figure 4.

The ball bearings with different types of damage are mounted in the bearing test module to generate the experimental data.

The rolling bearing module provides the possibility of using a test bearing under a constant radial load, which can be continuously adjusted up to 10 kN before each experiment.

An adapter gives the possibility to measure the vibration of the inner housing, which holds the test bearing in the main direction of the load. The precise design of the bearing module and additional features, such as the possibility to simulate tilting faults or the use of roller bearings, are described by Lessmeier, Enge-Rosenblatt, Bayer, & Zimmer, 2014.

The motor (1) is a 425 W Permanent Magnet Synchronous Motor (PMSM) with

- a nominal torque of T = 1.35 Nm,

- a nominal speed of n = 3,000 rpm,

- a nominal current of I = 2.3 A

- a pole pair number p = 4

(Type SD4CDu8S-009, Hanning Elektro-Werke GmbH & Co. KG)

It is operated by a frequency inverter (KEB Combivert 07F5E 1D-2B0A) with a switching frequency of 16 kHz. This standard industrial inverter is used to provide conditions similar to motors used in the industry because the current signals show significant noise due to the pulse-width modulation of the inverter. (Lessmeier, Piantsop Mbo'o, Coenen, Zimmer, & Hameyer, 2012)

Figure 5 shows the schema of the measurement procedure and the recorded measurands. The motor phase currents are measured by a current transducer of the type LEM CKSR 15-NP with an accuracy of 0.8% of I PN = 15 A. The MCS are then filtered by a 25 kHz low-pass filter and converted from an analogue to a digital signal with a sampling rate of 64 kHz. The current transducers are used instead of the internal ammeters of the inverter because of their easy signal access as the currents can be measured externally between motor and inverter.

At this scientific level of development, a high sampling rate and accuracy are additional advantages of this setup. Although, the used transducers are similar to the ones commonly used in industry applications, so that few difficulties are expected transferring the research outcomes to industrial CM systems.

The acceleration of the bearing housing is measured at the adapter at the top end of the rolling bearing module using a piezoelectric accelerometer (Model No. 336C04, PCB Piezotronics, Inc.) and a charge amplifier (Type 5015A, Kistler Group) with a low-pass filter at 30 kHz. The signal is digitalized and saved synchronously to the MCS with a sampling rate of 64 kHz.

The flywheel and the load machine simulate inertia and load of the driven equipment, respectively. The load motor is a PMSM with a nominal torque of 6 Nm (power of 1.7 kW).

To record the operating conditions the following additional parameters are measured synchronously to the motor currents and vibration signal but with lower sampling rates: the radial force on the bearings (Compression and Tension Force Sensor Type K11, Lorenz, 10 kN), the load torque at the torque-measuring shaft, the rotational speed (Torque Transducer Model 305, Magtrol, 2 Nm) and the oil temperature in the bearing module.

The rotational speed of the drive system, the radial force onto the test bearing and the load torque in the drive train are the main operation parameters. To ensure comparability of the experiments, fixed levels were defined for each parameter (Table 6).

All three parameters were kept constant for the time of each measurement. At the basic setup (Set no. 0) of the operation parameters, the test rig runs at n = 1,500 rpm with a load torque of M = 0.7 Nm and a radial force on the bearing of F = 1,000 N.

Three additional settings are used by reducing the parameters one by one to n = 900 rpm, M = 0.1 Nm and F = 400 N (set No. 1-3), respectively. For each of the settings, 20 measurements of 4 seconds each were recorded.

Another parameter is the temperature, which was kept roughly at 45 -50 ° C during all experiments.

| No. | Rotational speed [rpm] | Load Torque [Nm] | Radial force [N] | Name of Setting |

|---|---|---|---|---|

| 0 | 1500 | 0.7 | 1000 | N15_M07_F10 |

| 1 | 900 | 0.7 | 1000 | N09_M07_F10 |

| 2 | 1500 | 0.1 | 1000 | N15_M01_F10 |

| 3 | 1500 | 0.7 | 400 | N15_M07_F04 |

| Bearing Code | Run-in Period [h] | Radial Load [N] | Speed [min ^ -1] |

|---|---|---|---|

| K001 | > 50 | 1000-3000 | 1500-2000 |

| K002 | 19 | 3000 | 2900 |

| K003 | 1 | 3000 | 3000 |

| K004 | 5 | 3000 | 3000 |

| K005 | 10 | 3000 | 3000 |

| K006 | 16 | 3000 | 2900 |

-

Bin Hasan M. Current based condition monitoring of electromechanical systems. Model-free drive system current monitoring: faults detection and diagnosis through statistical features extraction and support vector machines classification. [D]. University of Bradford, 2013.

-

Lessmeier C, Kimotho J K, Zimmer D, et al. Condition monitoring of bearing damage in electromechanical drive systems by using motor current signals of electric motors: a benchmark data set for data-driven classification: Proceedings of the European conference of the prognostics and health management society, 2016 [C]. [Paper link] (https://mb.uni-paderborn.de/fileadmin/kat/PDF/Veroeffentlichungen/20160703_PHME16_CM_bearing.pdf)

-

Pandhare V, Singh J, Lee J. Convolutional Neural Network Based Rolling-Element Bearing Fault Diagnosis for Naturally Occurring and Progressing Defects Using Time-Frequency Domain Features [C] // 2019 Prognostics and System Health Management Conference (PHM-Paris). IEEE, 2019: 320-326. [Paper link] (https://ieeexplore.ieee.org/abstract/document/8756423)

-

Zhu Z, Peng G, Chen Y, et al. A convolutional neural network based on a capsule network with strong generalization for bearing fault diagnosis [J]. Neurocomputing, 2019, 323: 62-75. [Paper link] (https: //www.sciencedirect.com/science/article/pii/S0925231218311238) Convolutional neural network based on strong generalized capsule network for bearing fault diagnosis

-

Chen Y, Peng G, Xie C, et al. ACDIN: Bridging the gap between artificial and real bearing damages for bearing fault diagnosis [J]. Neurocomputing, 2018, 294: 61-71. [Paper link] (https: / /www.sciencedirect.com/science/article/pii/S092523121830300X) ACDIN: Bridging the gap between manual and real bearing damage for bearing fault diagnosis

-

Wu, J., et al., Sensors Information Fusion System with Fault Detection Based on Multi-Manifold Regularization Neighborhood Preserving Embedding. Sensors, 2019. 19 (6): p. 1440. [Paper link] (https: // www .mdpi.com / 1424-8220 / 19/6/1440) Sensor information fusion system based on multi-manifold regularization and preserving neighborhood embedding