Robotic hand project for actuators/power electronics and sensors/instrumentation university courses (PCB hardware).

STM32F446RE firmware repo: robotic_hand.

- System architecture is explained in further detail in this software repo.

Table of Contents

This project is sponsored by PCBWay. You can learn more about their valuable support here: 💖 Sponsors/PCBWay.

| Top | Bottom |

|---|---|

|

|

|

|

|

|

- Pictures show v0.1.0 production run. The second row is a software development variant and the bottom row is an enclosed no digital sensor variant assembly.

| Connector | Ref | Description |

|---|---|---|

| VL53L4CD Breakout | (J)U6 | Breakout connector for TOF sensor |

| USB-C 5 V power | J1 | Power only USB-C, primary 5 V source |

| Tag-Connect TC2050 | J2 | Programming/debug connector |

| Battery to buck (5 V) regulator | J3 | Pin 1: Ground, Pin 2: Battery supply (> 5 V, <= 36 V) |

| 5V Breakout | J4 | 5 V analog input 7 |

| BOOT0 jumper | J5 | Open for run flash memory (pull-down on open) |

| UART Breakout | J6 | General purpose UART breakout |

| WS2812B PWM LEDs | J7 | 5 V Addressable LED breakout |

| ADC 1 | J8 | 5 V analog input 1 |

| ADC 2 | J9 | 5 V analog input 2 |

| ADC 3 | J10 | 5 V analog input 3 |

| ADC 4 | J11 | 5 V analog input 4 |

| ADC 5 | J12 | 5 V analog input 5 |

| ADC 6 | J13 | 5 V analog input 6 |

| ADC 7 | J14 | 5 V analog input 7 |

| Unipolar Motor 1 | J15 | Robotic finger 1 motor |

| Unipolar Motor 2 | J16 | Robotic finger 2 motor |

| Unipolar Motor 3 | J17 | Robotic finger 3 motor |

| Unipolar Motor 4 | J18 | Robotic finger 4 motor |

| Unipolar Motor 5 | J19 | Robotic finger 5 motor |

| Switch/Jumper | Ref | Description |

|---|---|---|

| MCU NRESET switch | SW1 | Generic 6 mm TH button, push to reset |

| VL53L4CD breakout INT | JP1 | Open = no breakout, closed = bridge breakout INT line |

| BNO085 clock select | JP2 | Open = crystal, closed = external/internal |

- Production oriented 4-layer board variant.

- Designed for single production run given course project requirement.

- Order date: 2025/02/23.

- Order number:

W837000ASB9.

OrCAD X (PSpice) by Cadence was used for circuit simulation and evaluation.

Since this project relies heavily on Texas Instruments (TI) components (ADC ICs, Darlington transistor arrays, and buck regulators), PSpice was chosen for design verification and virtual testing. TI provides official PSpice models, making simulations more accurate and reliable.

Initially, PSpice for TI (a free version limited to TI parts) was used. Upgrading to OrCAD X enabled full compatibility and broader simulation capabilities.

KiCad was chosen for PCB design due to its ease of use as a free, open-source software. Additionally, prior experience and personal preference played a key role in the decision.

CLion and STM32CubeMX from STMicroelectronics were selected based on prior experience and personal preference. STM32CubeMX is utilized for initial component selection, pin configuration, and HAL software generation, while CLion is used for general C firmware development. For more details, see robotic_hand.

GitHub was chosen for its efficiency in version control and support for Actions automations. These automations facilitated testing, validation, and various manufacturing-related processes for both hardware and software development.

The LMR51430 was chosen for its wide input voltage range of 4.5 V to 36 V, high output current of 3 A and overall efficiency.

Datasheet: Datasheet: LMR51430 SLUSEF4A – JUNE 2022 – REVISED NOVEMBER 2022.

Big thanks, as always, to the amazing publicly available resources online 👑:

The expected current load is as follows:

| Load | Current | n |

|---|---|---|

| Motors + drivers | 500 mA | 5 |

| WS2812B LEDs | 60 mA | 1 |

| 3.3 V ICs via LDO | 100 mA | 1 |

Approximate total current draw: 2660 mA = 2.66 A at 5 V.

In a real-world engineering scenario, current draw would be estimated using more accurate models and measured across various revisions of development boards. However, due to budget constraints and the need to support future higher-voltage applications, a 3 A buck regulator was chosen, as it is a commonly available and cost-effective option.

While this provides only an 11% safety margin, it was deemed acceptable for early research and educational purposes. In the worst-case scenario, the board can also be powered by an external 5 V power supply if needed.

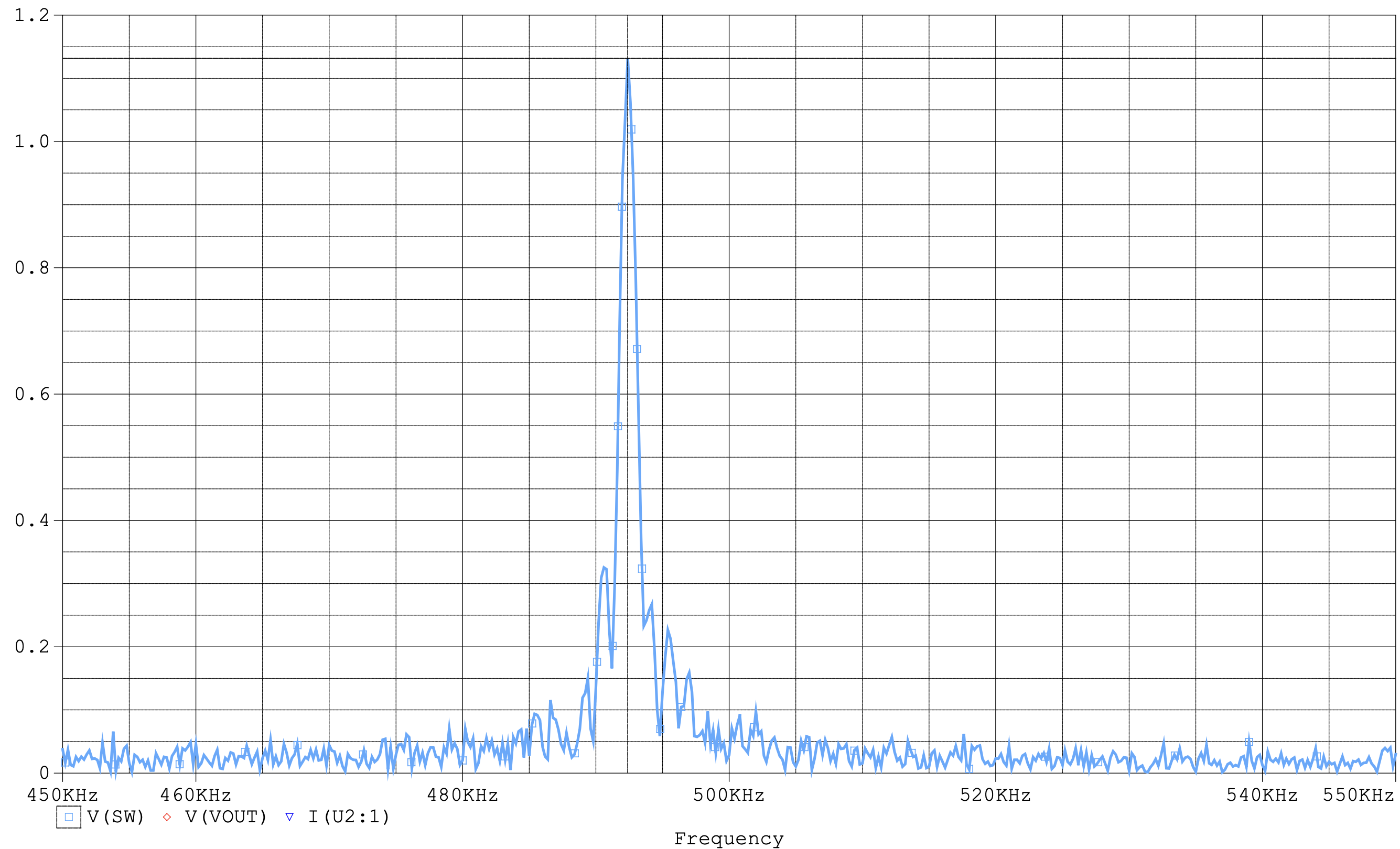

The LMR51430 is capable of 500 kHz and 1.1 MHz switching. The design opted for the 500 kHz configuration for reduced switching noise and its application of motor current driving. A lower switching frequency would theoretically reduce switching losses and improve efficiency at high current draw.

The following calculations are based on the recommendations provided in the LMR51430 datasheet.

The desired peak-to-peak ripple current is given by the following:

-

$L$ = Inductance driving ripple.

The minimum inductor specification is given by:

-

$K_{IND}$ = Coefficient representing the inductor ripple current as a fraction of the maximum output current, utilizing 0.3 for this project.-

A reasonable value of KIND must be 20% to 60% of maximum IOUT supported by the converter.

- Datasheet section: 9.2.2.4 Inductor Selection.

-

-

$f_{\text{SW}}$ = Switching frequency, 500 kHz chosen. -

$V_{\text{IN MAX}}$ = Input voltage, expected 12 V with ±1 V, 13 V. -

$V_{\text{OUT}}$ = Output voltage, 5 V. -

$I_{\text{OUT}}$ = Output current, approximately 3 A.

During an instantaneous over-current operation event, the RMS and peak inductor current can be high. The inductor saturation current must be higher than peak current limit level.

In general, choose lower inductance in switching power supplies because it usually corresponds to faster transient response, smaller DCR, and reduced size for more compact designs. Too low of an inductance can generate too large of an inductor current ripple such that over-current protection at the full load can be falsely triggered and generates more inductor core loss because the current ripple is larger. Larger inductor current ripple also implies larger output voltage ripple with the same output capacitors. With peak current mode control,ensure there is an adequate amount of inductor ripple current. A larger inductor ripple current improves the comparator signal-to-noise ratio.

- Datasheet section: 9.2.2.4 Inductor Selection.

The final minimum inductance value of 6.84 μH closely matches the example application values provided for a 12V input and 5V output, which uses 6.8 μH.

Minimize the output capacitance to keep cost and size down. The output capacitor or capacitors, COUT, must be chosen with care because it directly affects the steady state output voltage ripple, loop stability, and output voltage overshoot and undershoot during load current transient. The output voltage ripple is essentially composed of two parts. One part is caused by the inductor ripple current flowing through the Equivalent Series Resistance (ESR) of the output capacitors ... The other part is caused by the inductor current ripple charging and discharging the output capacitors.

- Datasheet section: 9.2.2.5 Output Capacitor Selection.

Inductor current ripple flowing through the ESR is given by:

Inductor current ripple charging and discharging the output capacitors is given by:

-

$K_{\text{IND}}$ = target ripple ratio of the inductor current ($\Delta i L / I_{\text{OUT}}$ ).

The minimum output capacitance needed for a specified output voltage overshoot and undershoot is given by:

-

$I_{\text{OL}}$ = low level output current during load transient. -

$I_{\text{OH}}$ = high level output current during load transient. -

$V_{\text{OUT SHOOT}}$ = target output voltage overshoot or undershoot.

For this project a target output ripple is arbitrarily set for 30 mV and the ripple ratio of inductor current is set to 0.3.

$\Delta V_{\text{OUT ESR}} = \Delta V_{\text{OUT C}} = 30 mV$ $K_{\text{IND}} = 0.3$

This yields ESR < 75 mΩ and output capacitance > 14 μF.

The LMR51430 device requires a high frequency input decoupling capacitor or capacitor. The typical recommended value for the high frequency decoupling capacitor is 4.7 μF or higher. TI recommends a high-quality ceramic type X5R or X7R with a sufficient voltage rating. The voltage rating must be greater than the maximum input voltage. To compensate the derating of ceramic capacitors, TI recommends a voltage rating of twice the maximum input voltage.

- Datasheet section: 9.2.2.5 Output Capacitor Selection.

Due to the limited availability of publicly accessible PSpice models, the LMR51420 model was used instead. Based on datasheet specifications, the 2A variant of the LMR514x0 series appears largely similar, with the primary difference being the requirement for a 10 μH inductor.

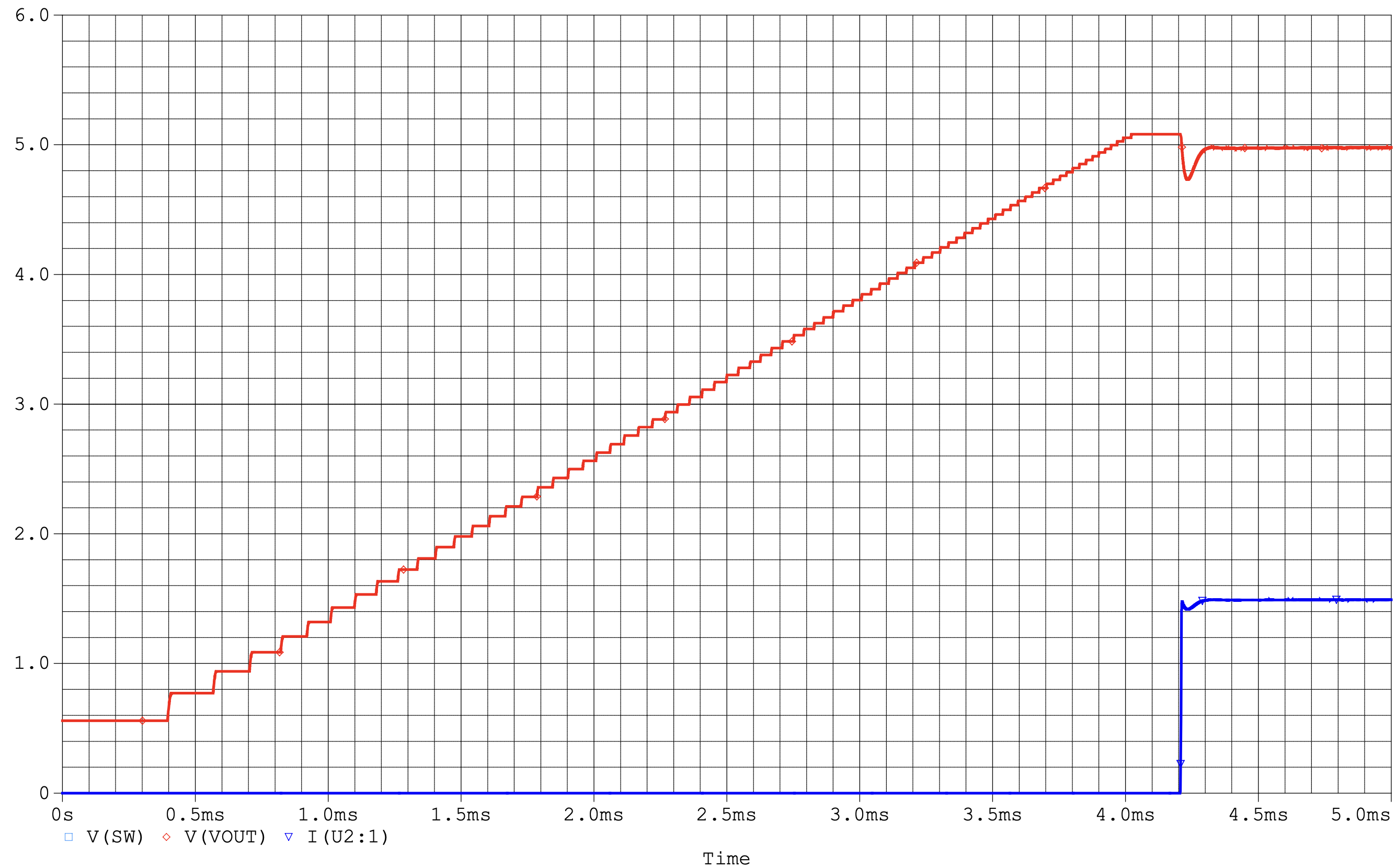

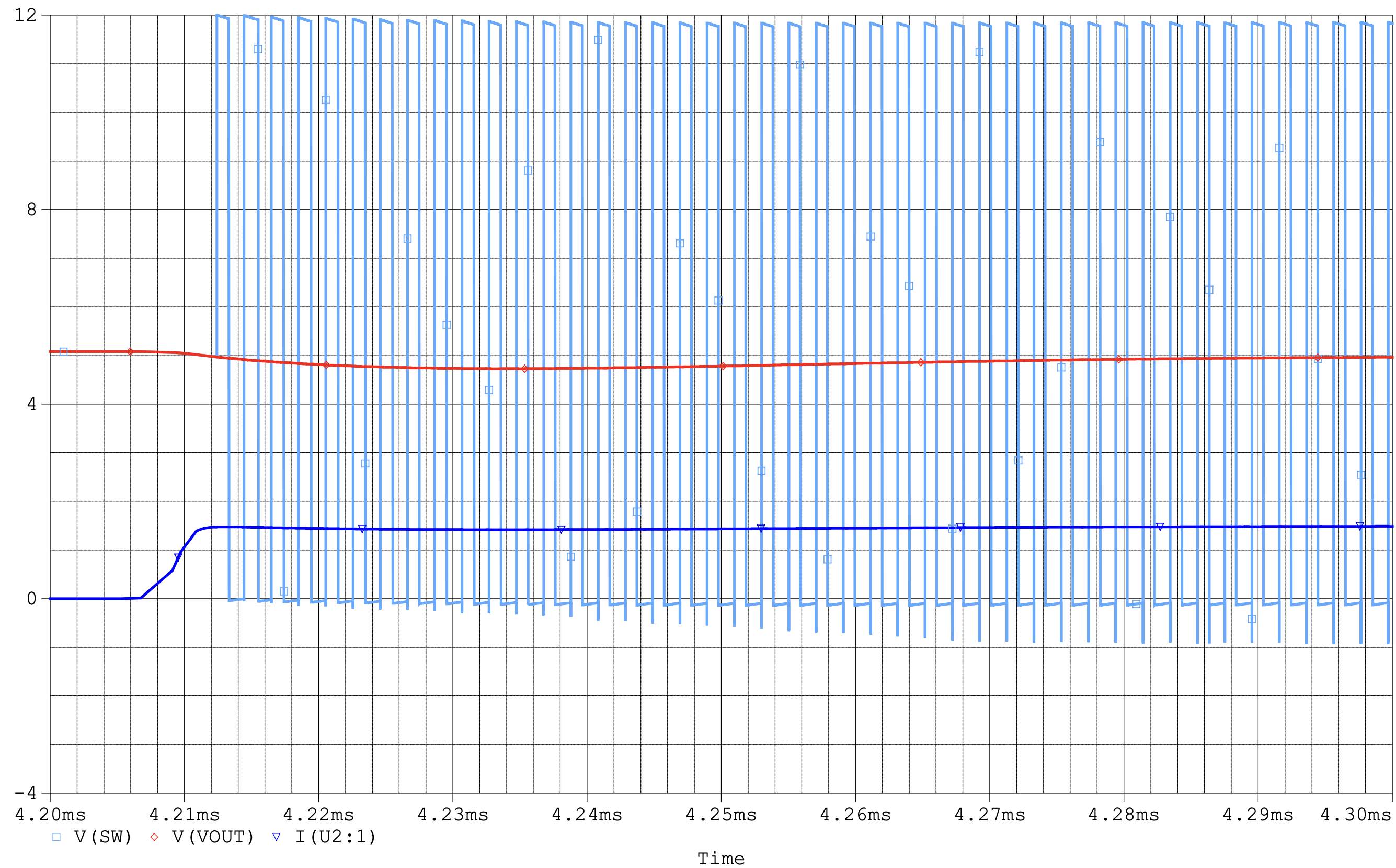

To simulate sudden current loads, a 3.3 Ω load (drawing 1.5 A at 5 V) is added and set to switch at 4.2 ms. The switch has a transition time of 15 μs.

For this simulation run, the fundamental frequency was found to be 492.400 kHz with a resultant amplitude of 1.1316. Due to the short simulation duration, the time required to ramp up to the final voltage, and the handling of sudden loads, it is hypothesized that the FFT results deviate slightly from the expected 500 kHz.

This project is sponsored by PCBWay, whose PCB manufacturing services are essential in producing high-quality prototypes for its development. Their support ensures reliable boards that meet the project's demands.

PCBWay stands out for their exceptional services and commitment to the community:

- PCB Manufacturing: High-quality fabrication with options for multilayer, rigid-flex, and advanced designs.

- PCB Assembly: Comprehensive solutions, including soldering, component sourcing, and assembly.

- CNC Machining & 3D Printing: Additional prototyping options to support complete product development.

- Fast Turnaround: Reliable and quick production times to keep projects on schedule.

- Support for Open Source & Education: PCBWay actively sponsors projects and

provides educational resources like tutorials, videos, and documentation,

empowering developers and hobbyists.

- This commitment to education and open-source advocacy was a key factor in choosing them as a partner 🙂.

Their dedication to professional-grade services and fostering innovation makes PCBWay an invaluable partner in bringing this project to life.

Learn more here: Why PCBWay?