- Submission notes

- Implementation notes*

- 1. Put robot back in initial state in Gazebo w/o restart

- 2. ROS2 objects

- 3. Adding a frame

- 4. tf2_ros::TransformListener for precision movement

- 5. Parametrizing the laser scanner

- 6. Logging

- 7. Using parameters and arguments from launch file

- 8. Attaching to the shelf/cart

- 9. Terminating a service

- 10. Rewriting approach and attachment to cart

- Warehouse servicing project

- 1. go_to_frame

- 2. Sending guidance TFs

- 3. Finding the midpoint

- 4. Solving for the relative TF yaw angle

- 3. Pick up the cart

- 4. Back up

- 5. Services

- 6. Parametrize position subscription

- 7. Publishing initial pose

- 8. Subscribing to amcl pose

- 9. Going from pose to pose

- 10. Oscillation on backing up

- 11. Rviz2 and Gazebo out of synch

- 12. Normal to line between reflective plates

- 13. "tf_cart_front_midpoint" coordinates are off

- 14. Bug in incidence TF

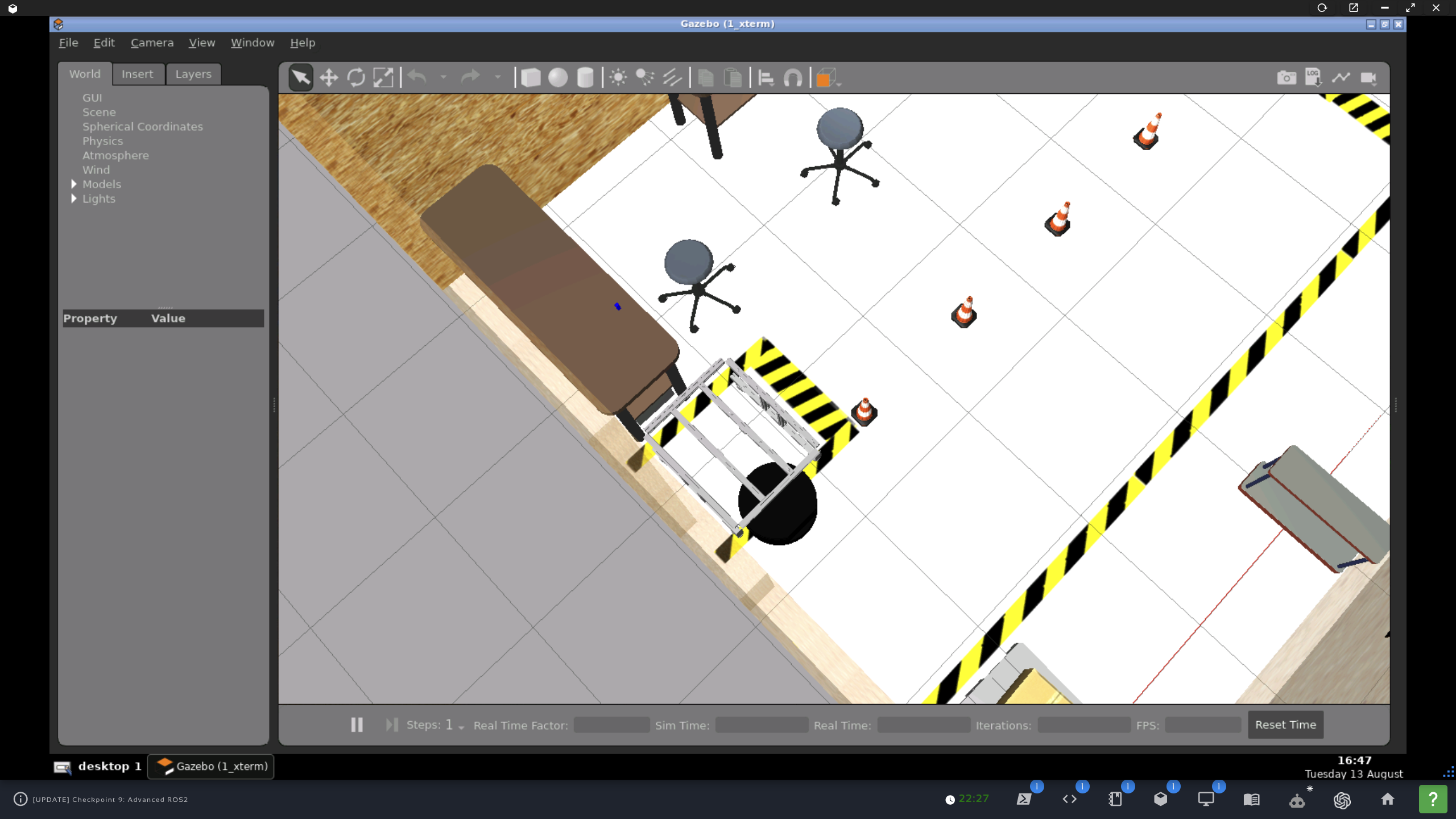

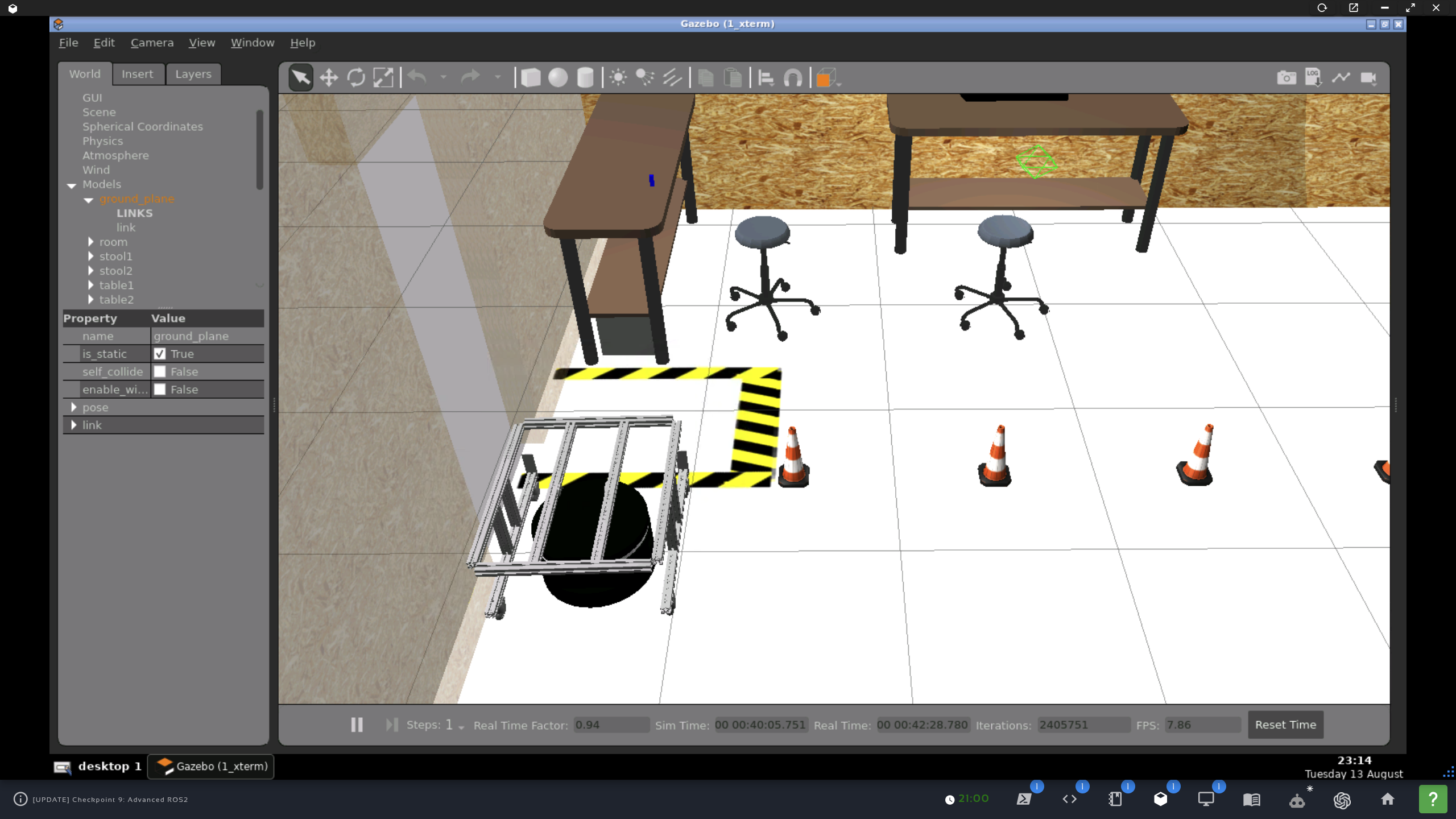

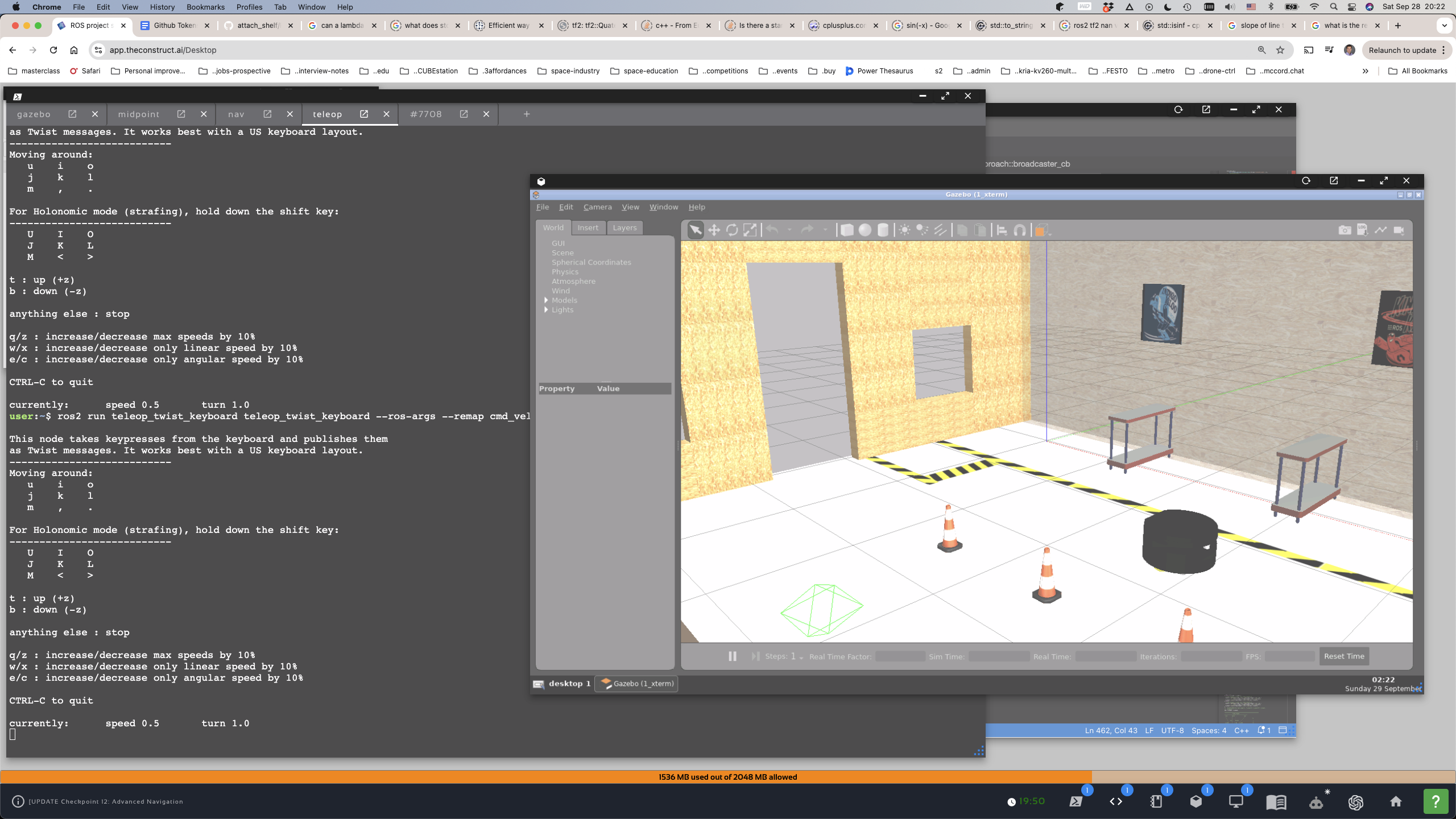

An RB1 robot in a warehouse world moves forward, turns, detects a shelf, moves underneath it and attaches to it by raising its elevator. Warehouse both simulated in Gazebo and a real physical playpen in the Barcelona office of The Construct.

- Launching

cd ~/ros2_ws/src git clone https://github.com/ivogeorg/attach_shelf.git checkout checkpoint-9-revised cd ~/ros2_ws colcon build --packages-select attach_shelf source install/setup.bash ros2 launch attach_shelf pre_approach.launch.xml obstacle:=0.39 degrees:=-92.0 - Note that the values for the arguments do not need to have such precision as the noise in the robot movement defeats them most of the time. It is not possible to achieve perfect alignment of the robot and the shelf/crate so that the robot can move underneath it by only going forward. The

/approach_shelfis more likely to achieve sufficient accuracy by using aTransformListenerand issue correctiveTwistmessages to the robot as it approaches. - Expected result

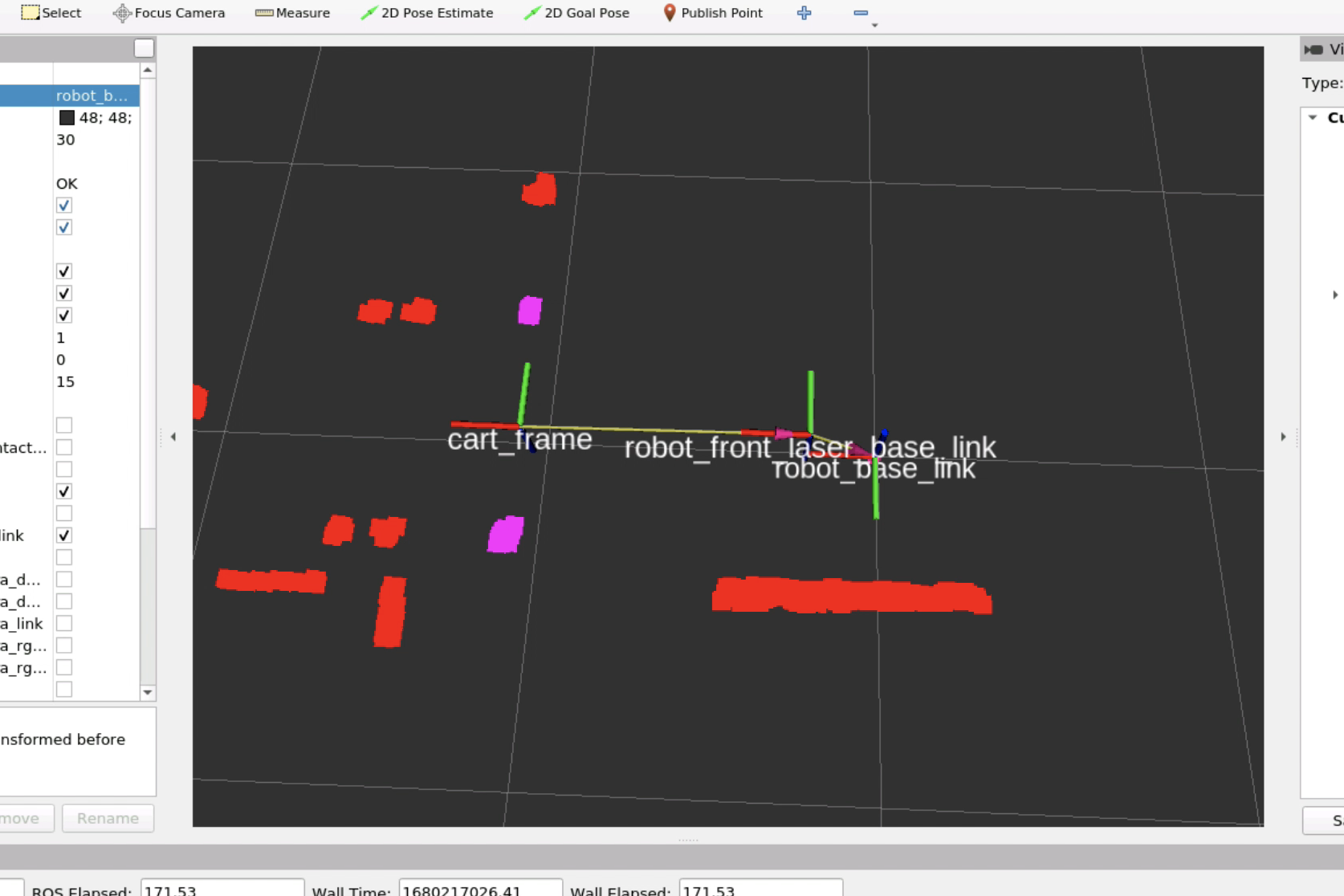

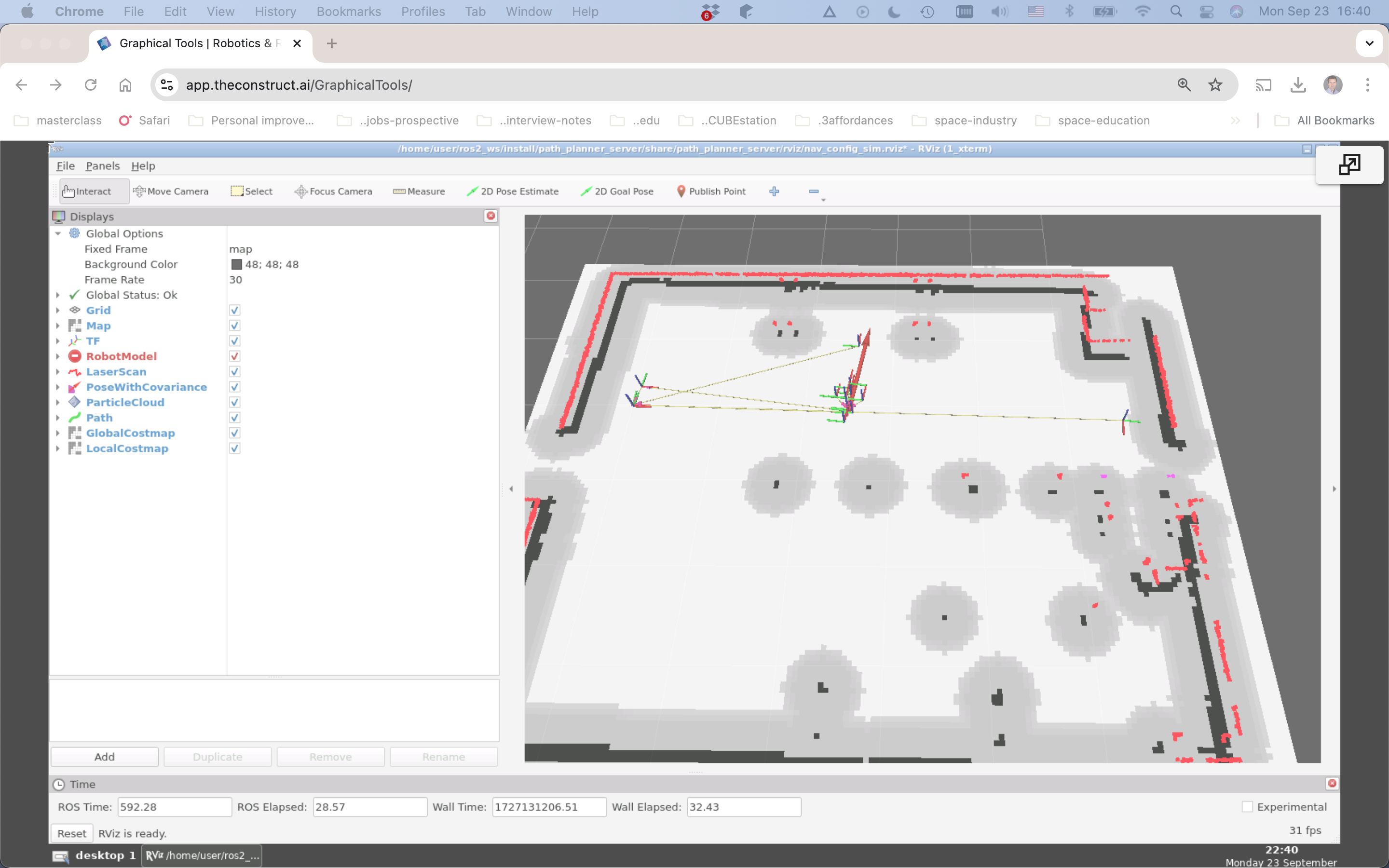

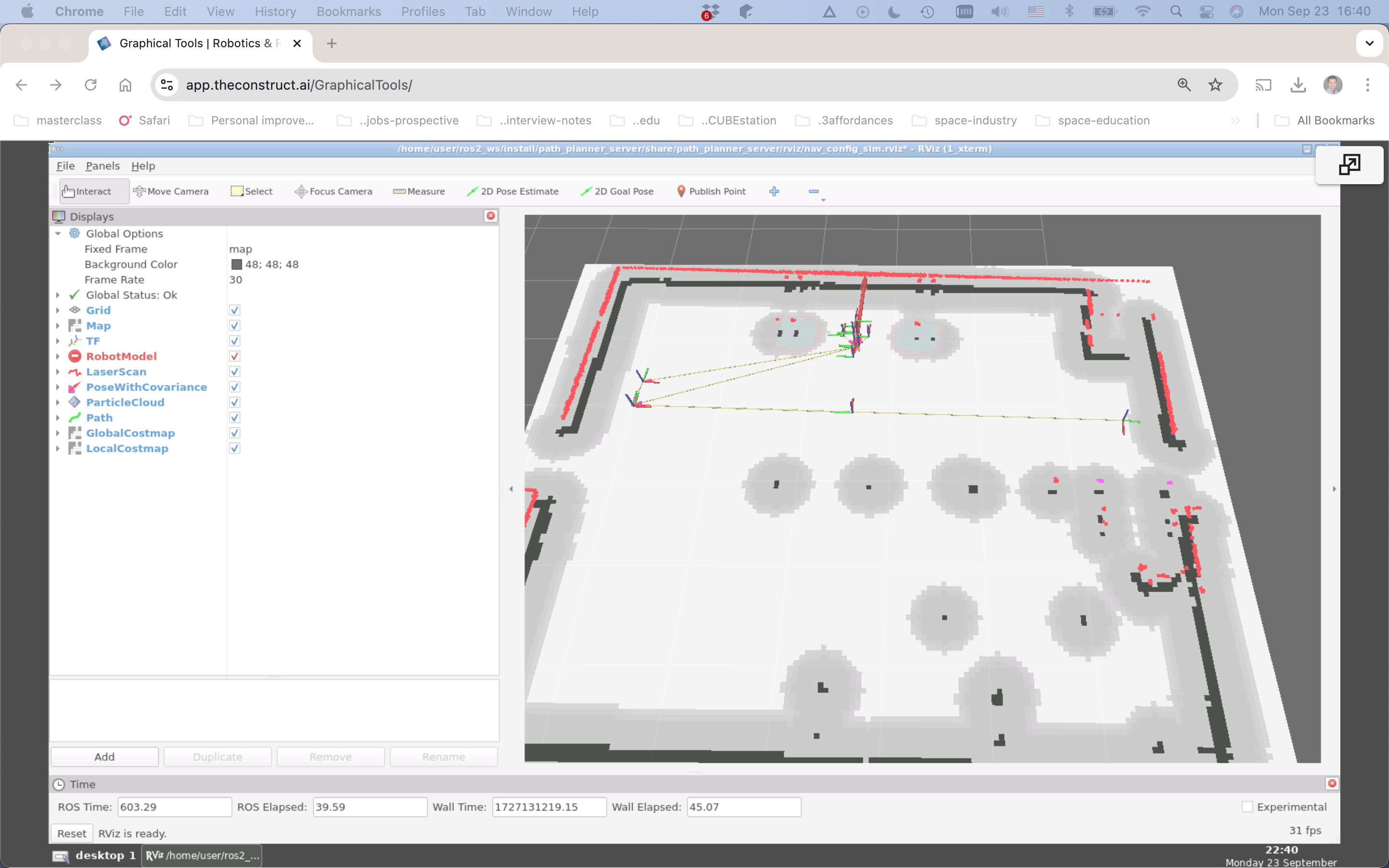

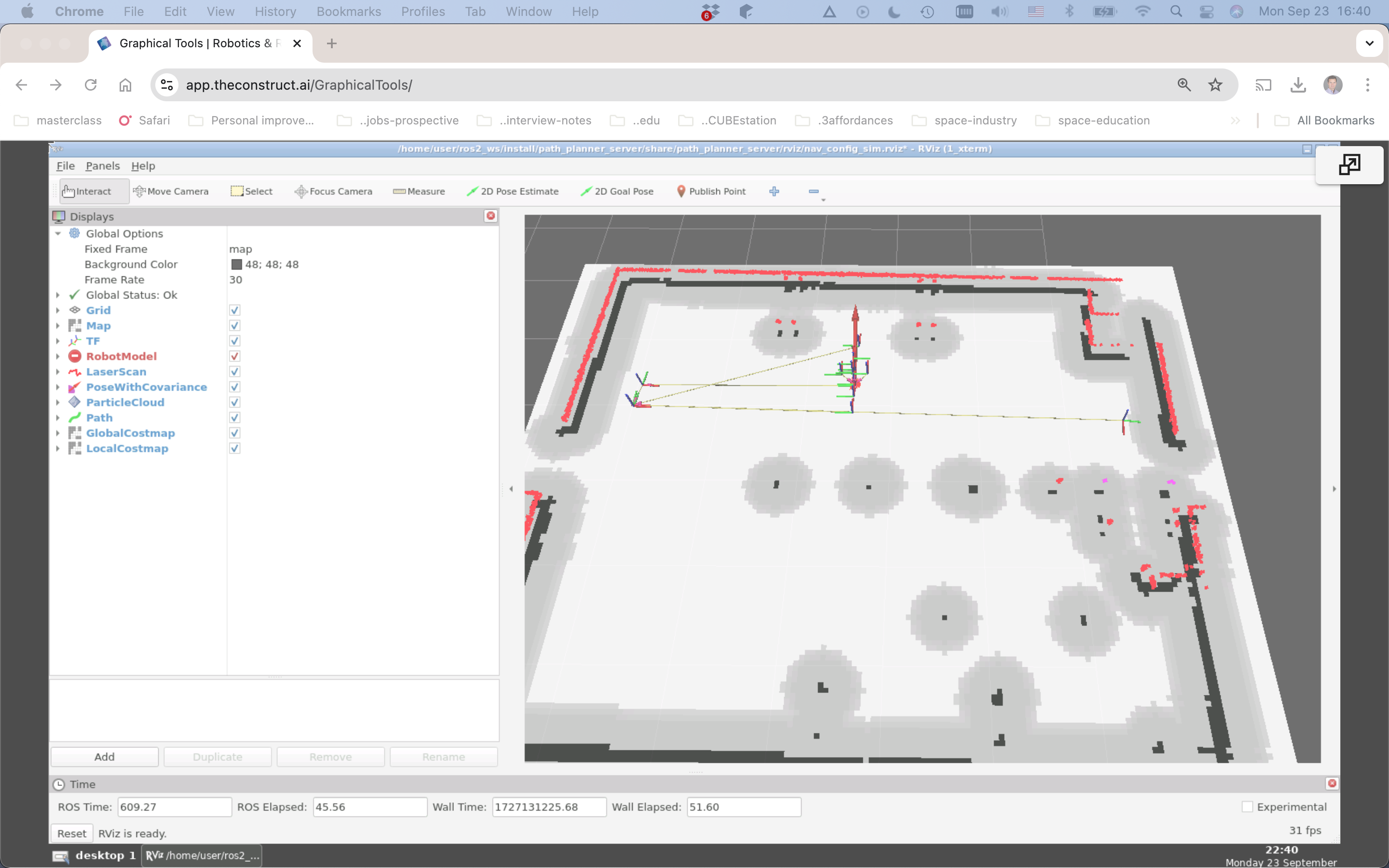

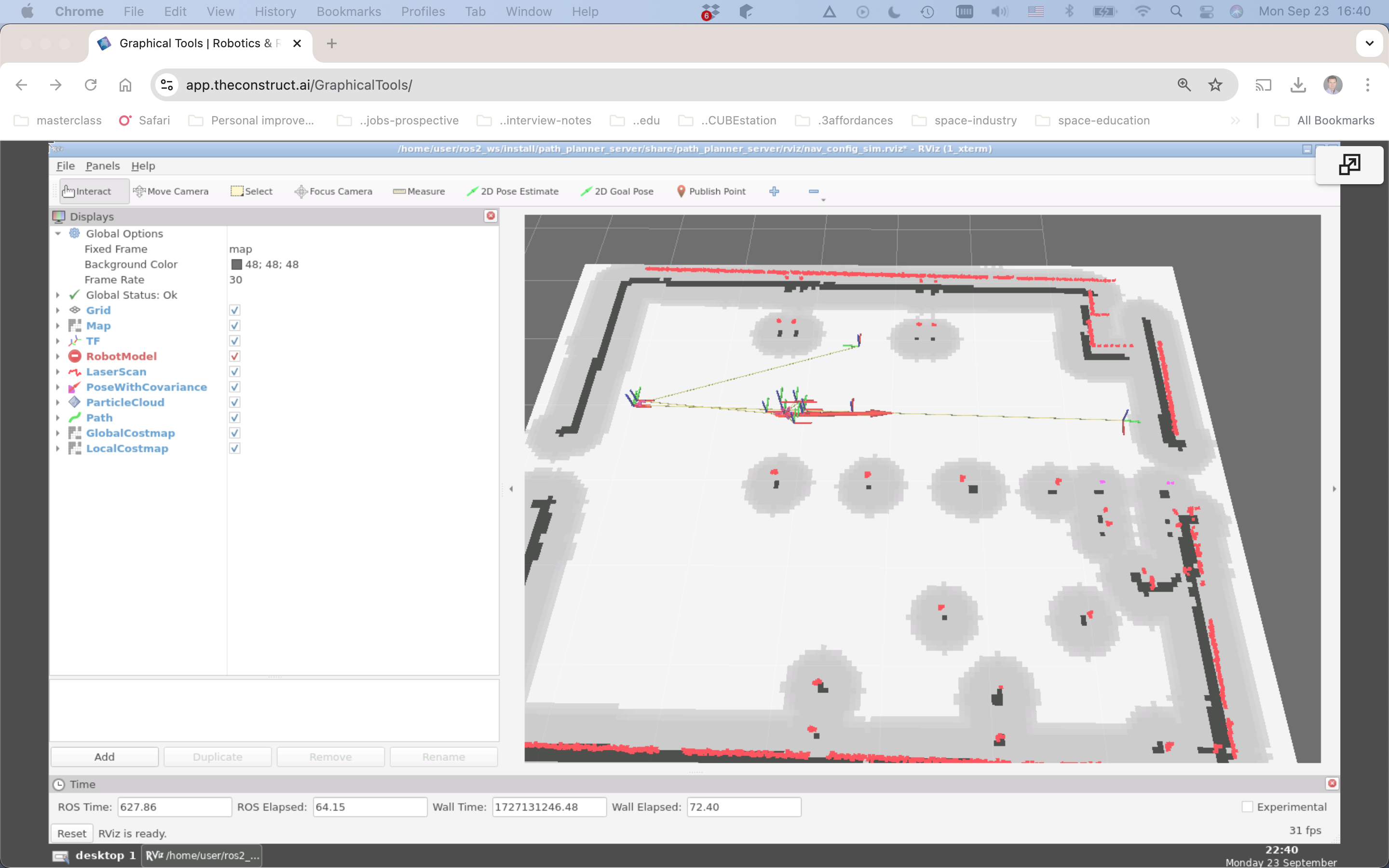

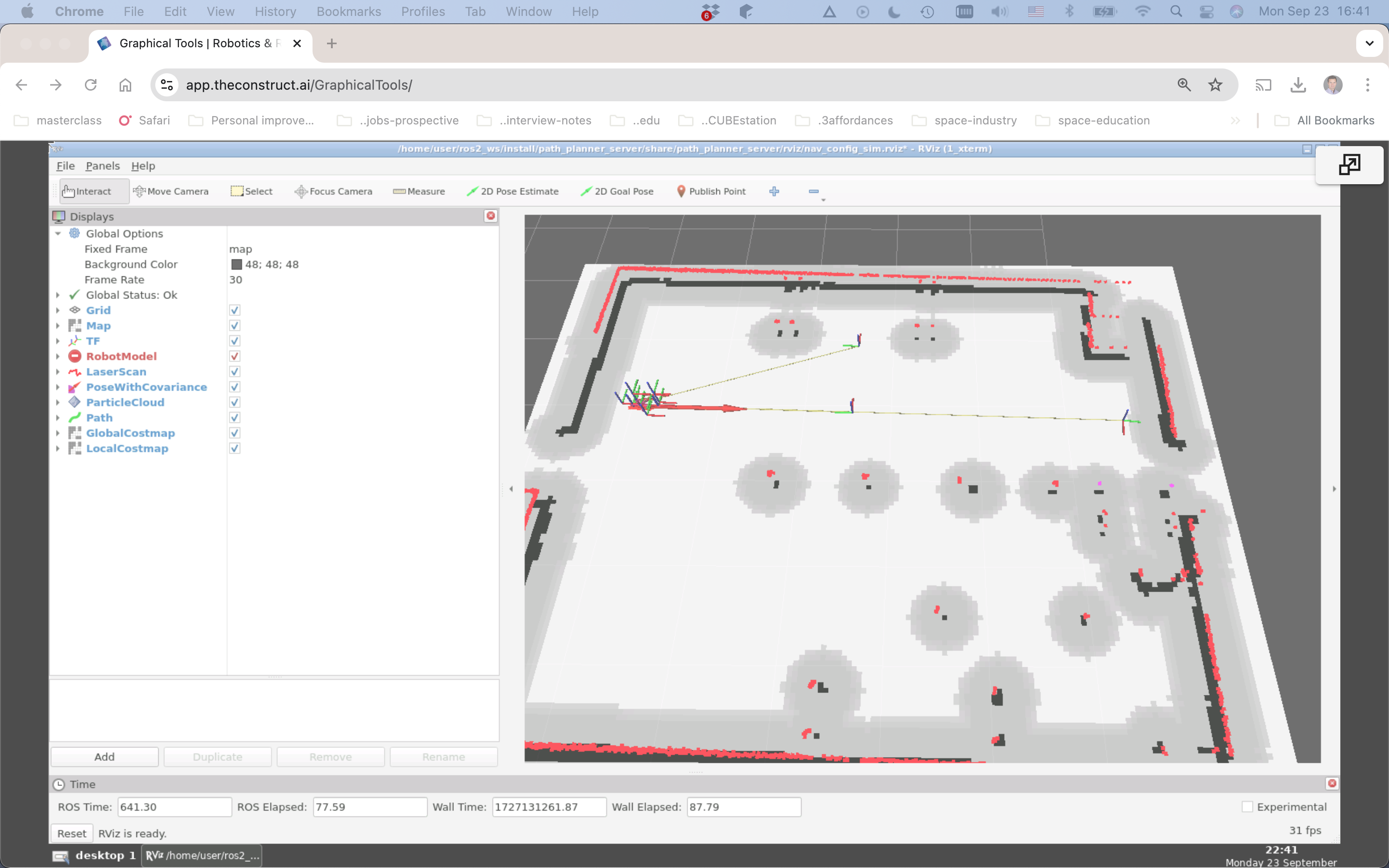

Gazebo Rviz2

- Launching

cd ~/ros2_ws/src git clone https://github.com/ivogeorg/attach_shelf.git checkout checkpoint-9-revised cd ~/ros2_ws colcon build --packages-select attach_shelf source install/setup.bash ros2 launch attach_shelf attach_to_shelf.launch.py obstacle:=0.30 degrees:=-90.0 final_approach:=true - Notes:

- There is a strange left-wheel slip front left of the cart which requires a complex navigation algorithm to compensate for automatically.

- The TF

cart_frameremains published ifattach_to_shelfisfalsebut stops broadcasting once the robot reaches it ifattach_to_shelfistrue. - The notebook is incorrect in its instructions about publishing to the

/elevator_uptopic. It's not of typestd_msgs/msg/Emptybutstd_msgs/msg/String. - Sending

msg.data=1causes the shelf/cart to be attached to the robot. Interestingly, the robot doesn't have to be underneath; the shelf/cart will "jump" to where the robot is and get attached. I have tried not to cheat with that. - Due to the signature of

Node::create_subscription(), where any callback group membership has to be indicated in theSubscriptionOptions, a simple derived classCustomSubscriptionOptionsis used to initialize an options object with a callback group object and then passed to the topic subscription creators.

- Expected result

Gazebo Rviz2

*Cumulative for both Task 1 and Task 2.

Optional

- Can use the

/demo/set_entity_stateservice to put the robot in the initial position for repeated testing. - The service is of type

gazebo_msgs/srv/SetEntityState. - The service server is provided by node

/demo/gazebo_ros_state. - Probably need to use

/demo/get_entity_stateto get the initial state.

- Subscriber to

/scan(sensor_msgs/msg/LaserScan). - Subscriber to

/odom(nav_msgs/msg/Odometry). - Publisher to

/diffbot_base_controller/cmd_vel_unstamped(geometry_msgs/msg/Twist). - Timer for velocity publisher.

- Server for service

/approach_shelf(customGoToLanding.srv). - Client to service

/approach_shelf(customGoToLanding.srv). - Publisher to

/elevator_up(std_msgs/msg/String). - Transform listener.

Need to add a frame in the middle of the reflective plates of the shelf.

- General approach:

- Use the

intensitiesarray of thesensor_msgs/msg/LaserScanto identify the points of incidence on the two reflective plates. The intensities should be significantly higher for them than for other points. - There should be two clusters. Use the

rangesto get their centers. Then find the midpoint between them. - Use this point to add a frame

cart_frameto the tree. Tutorial for adding a frame.

- Use the

- Algorithmic details:

- The origin frame of the scanner is

robot_front_laser_base_link. Using the angle of a ray and its measured range to a point can yield the point's frame. - The frames of the high-intesity points can be used for 3D k-means clustering, which will yield 1 or 2 clusters and the cluster centroids (with frames).

- From two points in 3D space, the midpoint between them can be found. The frame

cart_framecan be computed and arranged so that it represents a meaningful motion goal for the robot. - Using a transform between

robot_front_laser_base_linkandcart_frame, sendTwistmessages to the robot to move towardcart_frame. - Move the robot forward for 30 more cm. This can be done with another frame or with

Odomertydata.

- The origin frame of the scanner is

- The goal is:

- The

cart_framehas to be relative to the root of the world, in this caseodom, otherwise it will move with the robot. - The world coordinates of

cart_framcan be calculated by "adding" a transform from a known transform, say, betweenodomandrobot_front_laser_base_link, while the robot is stopped. Here is the latter TF:At time 1277.200000000 - Translation: [5.777, -0.147, 0.235] - Rotation: in Quaternion [-0.699, 0.715, -0.000, -0.000] - Rotation: in RPY (radian) [-3.142, -0.000, -1.592] - Rotation: in RPY (degree) [-180.000, -0.000, -91.230] - Matrix: -0.021 -1.000 -0.000 5.777 -1.000 0.021 -0.000 -0.147 0.000 -0.000 -1.000 0.235 0.000 0.000 0.000 1.000 cart_framewill only have anxand aycomponent (and possibly a yaw) relative torobot_front_laser_base_link. So, these are two transforms, which need to be combined, by matrix multiplication (except we don't have a matrix for the latter) or some other way. How to combine?- This is the SAS triangle diagram:

/*********************************************************** frame_length \------------|--y-->.------------------/ \rsa |pi/2 . lsa/ \ | . / \ | . / \ | . / +x \ h/x| .bisect / \ | . / ^ l_side\ | .--ba /r_side | \ |---ha \/ | \ |w . \ / +yaw /--|--\ -yaw \ |a. / V | V \ |y. / -y <----- | -----> +y \|./ (in laser link frame) V - sas_angle ***********************************************************/

| Gazebo | Rviz2 |

|---|---|

|

|

Briefly, after the RB1 robot has completed the pre-approach, has faced the crate/shelf, and has identified the two reflective plates, this TF needs to be added right in between the reflective plates. Questions:

- In the image showing the new TF in Rviz2,

cart_frameseems to be defined relative torobot_front_laser_base_link. The arrow points fromcart_frametorobot_front_laser_base_link. If the robot moves, won'tcart_framealso move? - If we use a

TransformBroadcasterinstead of aStaticTransformBroadcasterto definecart_framerelative torobot_front_laser_base_link, won't it still move to maintain the definition relative torobot_front_laser_base_link? - Shouldn't

cart_frame, which we need to stay in place to be used for moving the robot toward it, be defined in a transform fromodom(or whatever the root link in the TF tree is)? - If

cart_framewill move withrobot_front_laser_base_link, do we have to recalculate the point and modify the TF broadcast? That seems to be counterintuitive, not to mention difficult, because the reflective plates will disappear from "laser view" as the robot approaches the crate/shelf.

cart_frameshould be defined as a TF relative toodom.- Solve the SAS triangle. Get:

- The

xandycoordinates ofcart_framerelative torobot_front_laser_base_link. - Get the angle of

cart_framefromrobot_front_laser_base_link.

- The

- Use a

TransformBroadcasterto publishcart_framerelative torobot_front_laser_base_linkonce. - Use

tf_buffer.lookupTransformbetweenodomandcart_frame. - Use a

StaticTransformBroadcasterto publish the TF betweenodomandcart_frame. By default, this is published once. - Proceed with the final approach.

Note: All in code. No hardcoding!

- Solve the SAS triangle to get the

xandyoffsets betweenrobot_front_laser_base_linkandcart_frame. Call themx_offsetandy_offset. These offsets are relative to therobot_front_laser_base_linkframe. This frame is rotated, so the positivexaxis points forward and the positiveypoints -90 deg to the right. For completeness, the positivezaxis points down. Therefore:- The

x_offsetis always positive. - The sign of the

y_offsetdepends on the relative length of the ranges to the (innermost points of the) reflective plates. Note that the namesleft_rangeandright_rangeare correct due to the scanner rotating CW.- If

left_range > right_range,y_offsetis negative. - If

left_range < right_range,y_offsetis positive. - For completeness, if

left_range == right_range,y_offsetis zero (0.0). This is unlikely considering the precision of the ranges.

- If

- The

- Declare private

std::string source_frame_andstd::string target_frame_. They will serve as parameters for thetf_buffer_.lookupTransform(). Will require someboolvars to enforce the logic. - Declare private

geometry_msgs::msg::TransformStamped odom_laser_t_. It will hold the transformodomtorobot_front_laser_base_linkwhic, when the robot has completed the pre-approach, will be used to define the tranformodom_cart_fromodomtocart_frameby adding the offsetsx_offsetandy_offset. Then it will be zeroed out by assigning to a newly declared local variable. - Declare private

geometry_msgs::msg::TransformStamped odom_cart_t_. It will hold the transformodomtocart_frameto be used by TF to look up the tranformlaser_cart_t_. - Declare private

geometry_msgs::msg::TransformStamped laser_cart_t_. It will hold the transformrobot_front_laser_base_linktocart_frame, which will be broadcast for the final approach of the robot. - Declare private

std::unique_ptr<tf2_ros::Buffer> tf_buffer_. It will serve to calllookupTransform. It will serve two purposes:- If

source_frame_ == "odom"andtarget_frame_ == "robot_front_laser_base_link", keep updatingodom_laser_t_`. - If

source_frame_ == "robot_front_laser_base_link"andtarget_frame_ == "cart_frame", keep updatinglaser_cart_t_`.

- If

- Declare private

std::shared_ptr<tf2_ros::TransformListener> tf_listener_. It will serve to "wrap" thetf_buffer_. - Declare private

rclcpp::TimerBase::SharedPtr listener_timer_. It will serve to call the listener callback. - Declare private

void listener_cb(). It will calltf_buffer_.lookupTransform()withsource_frame_andtarget_frame_and enforce the logic of the dual use of the listener. - Declare private

std::shared_ptr<tf2_ros::TransformBroadcaster> tf_broadcaster_. It will serve to broadcastlaser_cart_t_for the final approach of the robot. - Declare private

rclcpp::TimerBase::SharedPtr broadcaster_timer_. It will serve to call the broadcaster callback. - Declare private

void broadcaster_cb(). It will calltf_broadcaster_->sendTransform(odom_cart_t_).

The final strategy, including some extra multithreading infrastructure, worked:

| Gazebo | Rviz2 | rqt_tf_tree |

|---|---|---|

|

|

|

At obstacle=0.45, robot can reach cart_frame without complex computations:

Notes on important details:

cart_framerequires transform chaining:

// Chain transforms

// Express the offsets in a new TransformStamped

geometry_msgs::msg::TransformStamped t;

// t.header.stamp = this->get_clock()->now();

t.header.stamp = odom_laser_t_.header

.stamp; // TODO: Will same work or should it be advanced?

t.header.frame_id = laser_frame_;

t.child_frame_id = cart_frame_;

t.transform.translation.x = x_offset;

t.transform.translation.y = y_offset;

t.transform.translation.z = 0.0;

t.transform.rotation.x = 0.0;

t.transform.rotation.y = 0.0;

t.transform.rotation.z = 0.0;

t.transform.rotation.w = 1.0;

tf2::Transform tf_odom_laser;

// Extract translation and rotation from TransformStamped

tf_odom_laser.setOrigin(tf2::Vector3(odom_laser_t_.transform.translation.x,

odom_laser_t_.transform.translation.y,

odom_laser_t_.transform.translation.z));

tf_odom_laser.setRotation(tf2::Quaternion(

odom_laser_t_.transform.rotation.x, odom_laser_t_.transform.rotation.y,

odom_laser_t_.transform.rotation.z, odom_laser_t_.transform.rotation.w));

tf2::Transform tf_laser_cart;

// Extract translation and rotation from TransformStamped

tf_laser_cart.setOrigin(tf2::Vector3(t.transform.translation.x,

t.transform.translation.y,

t.transform.translation.z));

tf_laser_cart.setRotation(

tf2::Quaternion(t.transform.rotation.x, t.transform.rotation.y,

t.transform.rotation.z, t.transform.rotation.w));

// Chain the transforms

tf2::Transform tf_odom_cart = tf_odom_laser * tf_laser_cart;

// Fill in the header of odom_cart_t_

odom_cart_t_.header.stamp = this->get_clock()->now();

odom_cart_t_.header.frame_id = odom_frame_;

odom_cart_t_.child_frame_id = cart_frame_;

// Directly assign the transform components

odom_cart_t_.transform.translation.x = tf_odom_cart.getOrigin().x();

odom_cart_t_.transform.translation.y = tf_odom_cart.getOrigin().y();

odom_cart_t_.transform.translation.z = tf_odom_cart.getOrigin().z();

odom_cart_t_.transform.rotation.x = tf_odom_cart.getRotation().x();

odom_cart_t_.transform.rotation.y = tf_odom_cart.getRotation().y();

odom_cart_t_.transform.rotation.z = tf_odom_cart.getRotation().z();

odom_cart_t_.transform.rotation.w = tf_odom_cart.getRotation().w();

// 2. Add a `cart_frame` TF frame in between them.

broadcast_odom_cart_ = true;

- To avoid a mismatch in Gazebo and ROS2 (system) times like this:

add

[INFO] [1723168735.547565617] [tf2_echo]: Waiting for transform robot_front_laser_base_link -> cart_frame: Lookup would require extrapolation into the past. Requested time 1234.377000 but the earliest data is at time 1723168725.641735, when looking up transform from frame [cart_frame] to frame [robot_front_laser_base_link]parameters=[{'use_sim_time': True}],to all launchedNode-s and get the intended outputAt time 445.299000000 - Translation: [-0.194, -0.739, -0.000] - Rotation: in Quaternion [-0.000, 0.000, 0.002, 1.000] - Rotation: in RPY (radian) [-0.000, 0.000, 0.003] - Rotation: in RPY (degree) [-0.000, 0.000, 0.175] - Matrix: 1.000 -0.003 -0.000 -0.194 0.003 1.000 0.000 -0.739 -0.000 -0.000 1.000 -0.000 0.000 0.000 0.000 1.000

- Use a

TransformListenerwithcart_frameandrobot_base_footprintframe of the robot to issue precision commands for the final approach. - Correct the pose of the robot before approach. Since the main linear approach will be guided by the TF between

robot_base_linkandcart_frame, butcart_framewas originally defined relative torobot_front_laser_base_link, the robot should travel forward along thexdimension (because the two frames are aligned) the distance betweenrobot_base_linkandrobot_front_laser_base_link, which is0.21as can be seen in the xacro file used to spawn the RB1 robot. - Precision movement impossible with drifting

odom/alone. Look at the following curve which should be a straight line as onlytwist.linear.xis non-zero:

[approach_shelf_service_server_node-1] [INFO] [1723821045.867948241] [approach_shelf_service_server_node]: Facing shelf

[approach_shelf_service_server_node-1] [DEBUG] [1723821045.867976347] [approach_shelf_service_server_node]: Turning goal -0.177402 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.177999427] [approach_shelf_service_server_node]: Done turning, turn angle = -0.167685 rad. Stopping

[approach_shelf_service_server_node-1] [INFO] [1723821050.178088714] [approach_shelf_service_server_node]: Approaching shelf

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.235157242] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.970213 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.235242511] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.970395 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.235272393] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.162756 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.235294622] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.727796, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.335098989] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.969543 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.335205083] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.969812 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.335228154] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.166941 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.335246967] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.727359, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.435108703] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.969058 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.435203106] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.969398 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.435222103] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.169893 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.435238035] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.727048, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.535098591] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.965476 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.535183547] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.965749 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.535200113] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.167109 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.535213499] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.724312, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.636371759] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.955244 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.636464956] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.955313 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.636491963] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.155189 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.636507694] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.716485, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.735103658] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.936957 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.735198605] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.936979 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.735217795] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.136205 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.735233826] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.702734, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.835137458] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.912663 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.835219296] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.913045 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.835237553] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.114726 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.835253748] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.684784, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.935139778] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.874568 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.935758391] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.876063 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.935791110] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.087078 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821050.935814381] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.657047, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.035099316] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.825127 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.035632817] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.827672 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.035659087] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.071019 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.035678365] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.620754, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.135104503] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.772894 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.135187029] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.776397 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.135215705] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.060013 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.135239651] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.582298, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.235129379] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.723856 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.235243788] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.728396 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.235267066] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.049951 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.235301822] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.546297, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.335102064] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.665056 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.335180271] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.670782 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.335200361] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.040934 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.335217314] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.503086, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.435127719] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.606691 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.435236627] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.613471 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.435261135] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.035429 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.435281358] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.460104, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.535128460] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.558758 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.535214377] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.566506 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.535248100] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.031259 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.535267693] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.424880, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.635126449] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.507998 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.635227591] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.516756 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.635253757] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.028703 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.635273973] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.387567, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.735144047] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.465699 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.735223598] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.475470 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.735242319] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.026318 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.735257421] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.356602, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.835128530] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.423901 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.835264070] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.434972 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.835288989] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.022675 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.835311558] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.326229, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.935105440] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.388800 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.935249940] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.401296 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.935279568] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.018103 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821051.935302570] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.300972, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.035124251] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.355402 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.035219365] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.369565 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.035243912] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.012808 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.035258709] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.277173, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.135146027] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.328086 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.135210455] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.343609 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.135225829] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.010514 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.135249608] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.257707, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.235143085] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.299225 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.235229176] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.316171 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.235246614] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.010490 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.235261579] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.237128, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.335209535] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.269846 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.335288833] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.288792 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.335306227] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.007812 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.335322407] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.216594, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.435171732] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.245975 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.435325927] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.266854 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.435359780] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.005496 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.435400607] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.200140, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.535165032] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.226066 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.535295960] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.248789 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.535325161] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.003815 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.535345537] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.186591, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.635109560] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.205016 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.635199054] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.229982 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.635224145] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.002245 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.635244333] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.172486, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.735123203] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.186445 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.735212125] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.213708 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.735235971] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.001035 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.735255852] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.160281, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.835159090] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.169233 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.835243257] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.198962 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.835262735] [approach_shelf_service_server_node]: listener_cb: error_yaw = 0.000050 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.835280738] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.149221, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.935136645] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.154531 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.935236240] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.186685 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.935258634] [approach_shelf_service_server_node]: listener_cb: error_yaw = -0.000705 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821052.935282623] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.140014, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.035202825] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.141952 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.035282336] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.176467 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.035304177] [approach_shelf_service_server_node]: listener_cb: error_yaw = -0.001301 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.035323889] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.132350, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.135140434] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.129482 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.135232621] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.166650 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.135256899] [approach_shelf_service_server_node]: listener_cb: error_yaw = -0.001884 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.135279732] [approach_shelf_service_server_node]: Moving robot toward `cart_frame` (x=0.124987, z=0.000000)

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.235124686] [approach_shelf_service_server_node]: listener_cb: delta_x = 0.118833 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.235209353] [approach_shelf_service_server_node]: listener_cb: error_distance = 0.158563 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.235238639] [approach_shelf_service_server_node]: listener_cb: error_yaw = -0.002433 rad

[approach_shelf_service_server_node-1] [INFO] [1723821053.235259054] [approach_shelf_service_server_node]: Moved robot within tolerance of `cart_frame`. Stopping

[approach_shelf_service_server_node-1] [INFO] [1723821053.235286327] [approach_shelf_service_server_node]: Straightening out

[approach_shelf_service_server_node-1] [DEBUG] [1723821053.235309073] [approach_shelf_service_server_node]: Turning goal 0.177402 rad

[approach_shelf_service_server_node-1] [DEBUG] [1723821056.946558923] [approach_shelf_service_server_node]: Done turning, turn angle = 0.167693 rad. Stopping

[approach_shelf_service_server_node-1] [INFO] [1723821056.946654420] [approach_shelf_service_server_node]: Moving under shelf

[approach_shelf_service_server_node-1] [DEBUG] [1723821056.946696232] [approach_shelf_service_server_node]: Linear motion goal 0.300000 m

[approach_shelf_service_server_node-1] [DEBUG] [1723821057.103055585] [approach_shelf_service_server_node]: Done moving, dist = 0.280398 m. Stopping

[approach_shelf_service_server_node-1] [INFO] [1723821057.103997161] [approach_shelf_service_server_node]: Attaching to shelf

[approach_shelf_service_server_node-1] [INFO] [1723821057.104510992] [approach_shelf_service_server_node]: Final approach completed

[pre_approach_v2_node-2] [INFO] [1723821057.104787266] [pre_approach_v2_node]: Final approach complete: 'true'

- Actually, the same happens without continous use of

lookupTransform. The robot consistently misses the goalcart_frameon the left (if starting from the left).

- This is a weird one!

angle_min: -2.3561999797821045 angle_max: 2.3561999797821045 angle_increment: 0.004363333340734243 time_increment: 0.0 scan_time: 0.0 range_min: 0.05999999865889549 range_max: 20.0 LaserScannerPokerfor reporting the parameters:[laser_scanner_poker_node-1] [INFO] [1722708445.226614735] [laser_scanner_poker_node]: angle_min = -2.356200 rad [laser_scanner_poker_node-1] [INFO] [1722708445.226731971] [laser_scanner_poker_node]: angle_max = 2.356200 rad [laser_scanner_poker_node-1] [INFO] [1722708445.226743815] [laser_scanner_poker_node]: angle_increment = 0.004363 rad [laser_scanner_poker_node-1] [INFO] [1722708445.226753163] [laser_scanner_poker_node]: range_min = 0.060000 rad [laser_scanner_poker_node-1] [INFO] [1722708445.226761269] [laser_scanner_poker_node]: range_max = 20.000000 rad [laser_scanner_poker_node-1] [INFO] [1722708445.226769927] [laser_scanner_poker_node]: ranges size = 1081- NOTE: Most importantly, it cycles CW so index 0 is at angle ~135 degrees, exactly the opposite of the standard direction and convention. See data/full_scanner.txt for a single run with the robot having completed the pre-approach and facing the cart/shelf. See the

infruns when the scanner passes through the two doors.

- Setting logging severity level (map frees from dependency on actual values):

std::map<int, std::string> levels = { {RCUTILS_LOG_SEVERITY::RCUTILS_LOG_SEVERITY_DEBUG, "DEBUG"}, {RCUTILS_LOG_SEVERITY::RCUTILS_LOG_SEVERITY_INFO, "INFO"}, {RCUTILS_LOG_SEVERITY::RCUTILS_LOG_SEVERITY_WARN, "WARN"}, {RCUTILS_LOG_SEVERITY::RCUTILS_LOG_SEVERITY_ERROR, "ERROR"}, {RCUTILS_LOG_SEVERITY::RCUTILS_LOG_SEVERITY_FATAL, "FATAL"} }; int level = RCUTILS_LOG_SEVERITY::RCUTILS_LOG_SEVERITY_INFO; if (rcutils_logging_set_logger_level(logger.get_name(), level) != RCUTILS_RET_OK) { RCLCPP_ERROR(logger, "Failed to set logger level '%s' for rb1_pre_approach_node.", (levels[level]).c_str()); } else { RCLCPP_INFO(logger, "Successfully set logger level '%s' for rb1_pre_approach_node.", (levels[level]).c_str()); } - Available settings (should not rely on these int values):

enum RCUTILS_LOG_SEVERITY { RCUTILS_LOG_SEVERITY_DEBUG = 0, RCUTILS_LOG_SEVERITY_INFO = 1, RCUTILS_LOG_SEVERITY_WARN = 2, RCUTILS_LOG_SEVERITY_ERROR = 3, RCUTILS_LOG_SEVERITY_FATAL = 4 }

-

Launch file declares parameters by name and default value, which is not enough by itself. See next step

<?xml version='1.0' ?> <launch> <!-- Launch the pre-approach node --> <node pkg="attach_shelf" exec="pre_approach_node" name="pre_approach_node"> <param name="obstacle" value="0.30" /> <param name="degrees" value="-90.0" /> </node> </launch> -

Node class constructor declares the parameters by name and gets their values. Now ROS2 knows about them

// Parameter: obstacle auto param_desc = rcl_interfaces::msg::ParameterDescriptor{}; param_desc.description = "Sets the distance (in m) from the wall at which the robot should stop to reach the shelf."; this->declare_parameter<std::double_t>("obstacle", 0.0, param_desc); this->get_parameter("obstacle", obstacle_); // Parameter: degrees param_desc.description = "Sets the degrees (in deg) the robot should turn to face the shelf."; this->declare_parameter<std::double_t>("degrees", 0.0, param_desc); this->get_parameter("degrees", degrees_); -

ROS2 reports the parameters for the node

user:~/ros2_ws/src/parameter_tests/yaml$ ros2 param list | grep -A 7 pre_approach_node /pre_approach_node: degrees obstacle qos_overrides./parameter_events.publisher.depth qos_overrides./parameter_events.publisher.durability qos_overrides./parameter_events.publisher.history qos_overrides./parameter_events.publisher.reliability use_sim_time -

To receive command-line arguments as in ros2 launch attach_shelf pre_approach.launch.xml obstacle:=0.3 degrees:=-90`, the XML launch file needs to delcare the arguments, as follows

<?xml version='1.0' ?> <launch> <arg name="obstacle" default="0.3"/> <arg name="degrees" default="-90.0"/> <!-- Launch the pre-approach node --> <node pkg="attach_shelf" exec="pre_approach_node" name="pre_approach_node"> <param name="obstacle" value="$(var obstacle)"/> <param name="degrees" value="$(var degrees)"/> </node> </launch> -

Launch arguments delcared in the Python launch file are sent through the

argvarray and can be extracted in a straightforward manner as, for example,turning_speed = std::stof(argv[2]);. The following allows the arguments to be specified in any order while passing it on to the executable in the the order declared, making the order predictable for the source code.

def generate_launch_description():

obstacle_arg = DeclareLaunchArgument(

"obstacle", default_value="0.30"

)

degrees_arg = DeclareLaunchArgument(

"degrees", default_value="-90.0"

)

obstacle_f = LaunchConfiguration('obstacle')

degrees_f = LaunchConfiguration('degrees')

pre_approach_node = Node(

package='attach_shelf',

executable='pre_approach_v2_node',

output='screen',

name='pre_approach_v2_node',

emulate_tty=True,

arguments=["-obstacle", obstacle_f,

"-degrees", degrees_f,

]

)

# create and return launch description object

return LaunchDescription(

[

obstacle_arg,

degrees_arg,

pre_approach_node

]

)

- Show arguments of a launch file

user:~/ros2_ws$ ros2 launch attach_shelf attach_to_shelf.launch.py --show-args

Arguments (pass arguments as '<name>:=<value>'):

'obstacle':

no description given

(default: '0.30')

'degrees':

no description given

(default: '-90.0')

'final_approach':

no description given

(default: 'false')

- The topic is

/elevator_upand is of typestd_msgs::msg::String. The reverse has the logical topic/elevator_down. - Need to send "data:

1" on the command line but from the python code inattach_client.pyit looks likemsg.data = 1. An empty string works, too:ros2 topic pub --once /elevator_up std_msgs/msg/String "{}" - There is visual change in that a white band appears in the middle of the robot in the simulator, and the cart may turn a bit. Also, anomalously, the cart flips so that the reflective plates go on the other side (closer to the desk). The lifting and setting down of the cart is clearly visible in the lab. It takes about 5 seconds to lift or set down completely.

- Interestingly enough, the shelf/cart doesn't have to be on top of the RB1 robot to attach to it. It would actually "jump" to position when

elevator_upis written to.

- Services are generally not terminated and/or restarted. It requires a whole bring-up which might involve restarting the whole system.

- If necessary (and benign), short of using a lifecycle node (note: lc nodes not fully developed), one can use a separate

TriggerorEmptycall to a "shutdown" service in the main service node, the callback for which can do some basic cleanup and callrclcpp::shutdown()after some time, say, 5-10 s.

- Service name will be

/cart_pick_up. - The general approach is to first align the robot's centroid with the lengthwise axis of the cart. This means that the distances to the reflective plates are equal. Then rotate to face along the midpoint between the plates and begin the approach. Possibly use the two supporting rods behind the plates to maintain alignment.

- Broadcast a static TF from

maptoload_pos_tfusing a composition of TF frommaptorobot_base_footprintand an all-zero TFrobot_base_footprinttoload_pos_tf. - Identify the reflective plates. Note that the intensity values vary with ambient light. In the original location,

intensities[i] > 3000works, but not universally. - Identify the smaller and larger distances to the two plates. Technically, these are the ranges of the rightmost ray of the left plate and the leftmost ray of the right plate.

- To align, go very slowly forward (

linear.x = 0.05) and to the farther plate (angular.z = 0.1) until the distances are equal. - Turn (the other way) until the ray indices are equally displaced on both sides of

front = 541. This means the robot is facing along the lengthwise axis of the cart. - Broadcast a static TF from

maptocart_frame_front_midpointusing a TF composition betweenmapandrobot_front_laser_base_linkand a TF fromrobot_front_laser_base_linktocart_frame_front_midpointwith the distance to the midpoint and all-zeros for the rest. - Broadcast a static TF from

maptocart_frame_centerpointusing a TF composition betweenmapandcart_frame_front_midpointand a TFrobot_frame_front_midpointandrobot_frame_centerpointwith an approximation of the cart half-length and all-zeros for the rest. - Approach the cart by using TF between

robot_base_footprintandcart_frame_front_midpointuntil tolerance. - Go under the cart by using TF between

cart_frame_front_midpointandcart_frame_centerpointuntil tolerance. Optionally, use the reflections to the supporting rods behind the reflective plates for alignment corrections. - Pick up the cart.

- Back up to

load_pos_tf.

"load_pos_tf": Usegeometry_msgs/msg/PoseStamped"loading_position"coordinates to create and publish TF"map"-"load_pos_tf""face_ship_pos_tf": Usegeometry_msgs/msg/PoseStamped"face_shiping_position"coordinates to create and publish TF"map"-"face_ship_pos_tf""cart_frame_front_midpoint": Create"map"-"cart_frame_front_midpoint"by composing"map"-"robot_front_laser_base_link"and"robot_front_laser_base_link"with added coordinates of midpoint between edges of reflective plates."cart_frame_centerpoint": Create"map"-"cart_frame_centerpoint"by composing"map"-"cart_frame_front_midpoint"and"cart_frame_front_midpoint"with added calculated distance between reflective plate midpoint and cart centerpoint."laser_origin_offset": Create"map"-"laser_origin_offset"by composing"map"-"robot_base_footprint"and"robot_base_footprint"-"robot_front_laser_base_link"without thezcoordinate.

| TF name | Parent frame | Composition frame | PoseStamped |

Depends on robot | TF composition |

|---|---|---|---|---|---|

"load_pos_tf" |

"map" |

loading_position |

No | No | |

"face_ship_pos_tf" |

"map" |

face_shipping_position |

No | No | |

"cart_frame_front_midpoint" |

"map" |

"robot_front_laser_base_link" |

Yes | Yes | |

"cart_frame_centerpoint" |

"map" |

"cart_frame_front_midpoint" |

No | Yes |

Notes on screenshot above:

- Two static TFs

"tf_load_pos"and"tf_face_ship_pos"are sent and visualized in Rviz2. - The parent frame is

"map", so navigation needs to be running. - The node containing the

StaticTransformBroadcasterwhich publishes the TFs needs to sleep for 2 seconds before it terminates for the TFs to be registered. - These TFs are to be used as targets for the robot to back up, from having picked up the cart and having set it down, respectively.

Goal: listener_cb is on a timer so that a changing transform is used to program motion dynamically. However, this makes the function cluttered and/or an if..else cascade. How can this be done elegantly?

- Move forward to

"laser_origin_offset". - Move forward to

"cart_frame_front_midpoint". - Move forward to

"cart_frame_centerpoint". - Move backward to

"tf_load_pos"(with cart). - Move backward to

"tf_face_ship_pos"(without cart). Note that the first 0.3 m the robot has to move straight back to clear the cart before it backs up (possibly not straight back) to "tf_face_ship_pos".

Possible solution 1:

- All of these have

"robot_base_footprint"as parent frame. - Can set global

child_frame_idexternally tolistener_cb. - All motions are linear. Only have to correct for angle by setting

angularin the opposite direction of the difference. How to do this directly in the quaternion?

Possible solution 2:

- Function

movethat takes direction and linear speed, parent and child frames, velocity publisher and transform listener buffer, aboolean &done, and other parameters as necessary. - Construct timer in the function, bind a lambda callback to do

lookupTransformand publishtwist, and setdonewhen motion complete (per the TF), and add timer to callback group. moveblocks ondoneuntil lambda sets it when the motion is complete (within tolerance, which can be a parameter with a default).

- When approaching the cart, with only forward motion set (

teleoporcmd_vel) the robot turns to the left and has to be corrected!ll - When the robot picks up the cart, the cart flips so that the reflective plates are on the other side.

- When decreasing/increasing speeds in

teleop, the robot moves. - Once picked up and set down, subsequent commands to

/elevator_*don't have a "physical" effect.

- There are 3 frames,

robot_cart_laser,robot_cart_laser_noisy, androbot_cart_laser_noisy_0, which are set wherecart_frameis meant to be set, and when the robot is facing the cart straight in. It appears and then fades, then appears again, possibly being published dynamically and going stale, and then published again. - The

robot_front_laser_base_linkis rotated -180 deg aroundxin the simulator, but only -90 deg arouncxin the lab!

This package is used as a submodule in the warehouse_project. It is undergoing a substantial rework.

Works fine forward and backward in the simulator once the AMCL parameters update_min_a and update_min_d were set to positive values.

| go_to_frame |

|---|

|

|

|

|

|

Face the cart, broadcast "cart_frame_front_midpoint" and "cart_frame_centerpoint".

This may take a few tries, where the robot backs up to start a new try. Here's an approximate strategy:

- Not necessary to be facing straight in to localize the midpoint. Moreover, it is much more difficult to achieve that than what is described here. Use the ranges and angles of the edge rays (or TFs, if published) to localize the midpoint.

- Compute the normal and calculate the yaw that corresponds to it.

- (Optional) Un-roll the relative TFs so that

go_to_framewould work correctly without - (Optional) Gather a cluster of midpoints and calculate the mean position.

- Use

go_to_frameusing the guidance TFs"cart_frame_front_midpoint"and"cart_frame_centerpoint".

| Gazebo | Rviz2 |

|---|---|

|

|

TFs unrolled:

| Gazebo | Rviz2 |

|---|---|

|

|

Have to solve for the angle of the TF "cart_frame_front_midpoint" relative to "robot_front_laser_base_link". Here is a sketch of the general case:

The goal angle is highlighted in the sketch and its between the forward direction of "robot_front_laser_base_link" and the normal to LR going through the midpoint M. It is possible to find this angle using trigonometry and knowns starting with the AR and AL ranges and the angle RAL between them.

There appear to be two singularities in this problem definition, when mid_theta is either 90 deg or 0 deg, both of which can only happen if the origin of the laser rays (which is defined in the URDF/Xacro model files to be the origin of "robot_front_laser_base_link") lies on the LR normal through M. In the first case the relative yaw of "cart_frame_front_midpoint" is 90 deg_ and, in the second, 0 deg. Another simplifying case is when the origin of the laser rays is on the normal, but the angle relative to RL is in (0, 90). In that case, the relative TF yaw angle is 90 - mid_theta. Note that this suggests the benefit of a solution that contains a reliable algorithm to stop the robot with the laser origin lying on the LR normal through M. This approach is sketched out in the next section.

This relies on getting the two ranges AL and AR to be equal (within a small tolerance). Depending on the current yaw of the robot, one of the three simplifying solutions above can be used.

- Solve the LAR triangle by the SAS method with AR, LR, and the angle <LAR known. This yields the angle <ARL, among other things.

- The angle <RAM is known (half of <LAR), so using the sum of the angles of a triangle, get the angle <AMR.

- The angle <MAS is known (

mid_theta) and the angle <AML is 180 - <AMR, so get the angle <MNS. - In the triangle MNS, the goal angle is the angle <MSN and that is 90 - <MNS.

Without service, use the fixed frames in (2) to move in underneath the cart and pick it up.

Use "tf_load_pos" to back up with the cart to where navigation can be switched to BasicNavigator::goToPose() again.

This package will serve 3 services to be used for moving carts from loading to shipping. attach_shelf should be renamed.

"cart_pick_up": approach, go under, pick up (go_to_frame()), back to"tf_load_pos""cart_set_down": (go to"tf_ship_pos"), set down, back up (move()), back to"tf_face_ship_pos"

warehouse_serviceswarehouse_cartcart_servicingwarehouse_cart_servicingwarehouse_cart_services*

- If not run along with

nav2, useodom, otherwise useamcl_pose. - Initialize a variable

position_sub_, creating a subscription for the correct type,nav_msgs::msg::Odometryforodomandgeometry_msgs::msg::PoseWithCovarianceStampedforamcl_pose. - This will require initilization after parameter reading, that is, in the constructor body.

- If both exist (for which there might be a use case), there will be two separate callbacks which can assign

last_yaw_. This will bury the logic (and the source) too deep in the code. - Two different descriptive variables so the usage will be localized in

rotateandgo_to_frame. There, the parameter will already have been read and there can be private fields to use in conditional assignments. Note that there might be the need to assign a reference so the live value is used in the loops. - Ultimately,

get_current_yaw()is a convenient single place to localize the logic.

rotate() didn't work with yaw taken from amcl_pose. TODO: Investigate. Also, how to know the frequency publication for a topic.

Solution:

ros2 topic hz /topic_name- This ROS answer explains the low frequency of

/amcl_poseand how to configure for faster publication.

Verified:

user:~$ ros2 topic hz /amcl_pose

WARNING: topic [/amcl_pose] does not appear to be published yet

average rate: 19.295

min: 0.000s max: 0.112s std dev: 0.05080s window: 20

average rate: 19.115

min: 0.000s max: 0.112s std dev: 0.05124s window: 40

average rate: 19.043

min: 0.000s max: 0.112s std dev: 0.05139s window: 60

average rate: 19.014

min: 0.000s max: 0.114s std dev: 0.05146s window: 80

average rate: 18.996

min: 0.000s max: 0.114s std dev: 0.05143s window: 100

average rate: 18.859

min: 0.000s max: 0.120s std dev: 0.05178s window: 120

user:~$ ros2 topic hz /scan

average rate: 17.553

min: 0.048s max: 0.069s std dev: 0.00578s window: 19

average rate: 17.620

min: 0.041s max: 0.073s std dev: 0.00774s window: 37

average rate: 17.856

min: 0.041s max: 0.079s std dev: 0.00764s window: 56

average rate: 17.928

min: 0.037s max: 0.079s std dev: 0.00856s window: 75

average rate: 17.992

min: 0.037s max: 0.079s std dev: 0.00815s window: 94

average rate: 17.977

min: 0.037s max: 0.079s std dev: 0.00791s window: 112

average rate: 18.053

min: 0.037s max: 0.079s std dev: 0.00786s window: 131

odom is all over the place, resulting in weird current yaw report. See figure below:

Gist:

The from-code publish:

- Sometimes works fine:

- Is caught by

ros2 topic echo /initialpose - Starts AMCL localization

- Is caught by

- Sometimes works partially:

- Is caught by

ros2 topic echo /initialpose - Fails to start AMCL localization

- Is caught by

- Sometimes doesn't work:

- Is not caught by

ros2 topic echo /initialpose - Fails to start AMCL localization

- Is not caught by

Avoiding the problem:

- Change

set_initial_pose: trueand setinitial_poseparameter values (x,y,z,yaw) with"init_position". - Use this 3D Rotation Converter to get the yaw from the orientation quaternion of the pose.

Gist:

The problem is illustrated by this log snippet:

user:~/ros2_ws$ ros2 launch attach_shelf cart_approach_test.launch.py

[INFO] [launch]: All log files can be found below /home/user/.ros/log/2024-09-19-02-52-58-926816-1_xterm-15685

[INFO] [launch]: Default logging verbosity is set to INFO

[INFO] [cart_approach_test_node-1]: process started with pid [15694]

[cart_approach_test_node-1] [INFO] [1726714379.041771216] [cart_approach_test_node]: Cart approach testingsandbox started

[cart_approach_test_node-1] [INFO] [1726714379.041939760] [cart_approach_test_node]: Successfully set logger level 'DEBUG' for cart_approach_test_node.

[cart_approach_test_node-1] [DEBUG] [1726714379.141895659] [cart_approach_test_node]: test_cart_approach

[cart_approach_test_node-1] [DEBUG] [1726714379.142042067] [cart_approach_test_node]: Cancelled timer

[cart_approach_test_node-1] [DEBUG] [1726714379.142065324] [cart_approach_test_node]: Robot autolocalized at pos_x: 0.000000, pos_y: 0.000000, ori_z: 0.000000, ori_w: 1.000000 Cov [x=0.000000, y=0.000000, z=0.000000]

[cart_approach_test_node-1] [DEBUG] [1726714380.487671962] [cart_approach_test_node]: amcl_pose:: pos_x: 0.000000, pos_y: 0.000000, ori_z: 0.000000, ori_w: 1.000000 Cov [x=0.000000, y=0.000000, z=0.000000]

[cart_approach_test_node-1] [DEBUG] [1726714380.565140191] [cart_approach_test_node]: amcl_pose:: pos_x: 0.028726, pos_y: -0.020338, ori_z: -0.014508, ori_w: 0.999895 Cov [x=0.000000, y=0.000000, z=0.000000]

[cart_approach_test_node-1] [DEBUG] [1726714380.713129984] [cart_approach_test_node]: amcl_pose:: pos_x: 0.028727, pos_y: -0.020338, ori_z: -0.014508, ori_w: 0.999895 Cov [x=0.000000, y=0.000000, z=0.000000]

[cart_approach_test_node-1] [DEBUG] [1726714380.793686755] [cart_approach_test_node]: amcl_pose:: pos_x: 0.028728, pos_y: -0.020338, ori_z: -0.014507, ori_w: 0.999895 Cov [x=0.000000, y=0.000000, z=0.000000]

[cart_approach_test_node-1] [DEBUG] [1726714380.869737076] [cart_approach_test_node]: amcl_pose:: pos_x: 0.028729, pos_y: -0.020338, ori_z: -0.014506, ori_w: 0.999895 Cov [x=0.000000, y=0.000000, z=0.000000]

Observations:

- The

amcl_pose_callbackis called too late. - The first callback carries an all-zeros AMCL pose.

Solution (simulator):

- Start before

amcl. - Publish to

/intitialposein a loop. - Terminate at a valid

/amcl_posemsg.

geometry_msgs::msg::PoseWithCovarianceStamped initialpose;

initialpose.header.stamp = this->get_clock()->now();

initialpose.header.frame_id = "map";

initialpose.pose.pose.position.x = init_position_[0];

initialpose.pose.pose.position.y = init_position_[1];

initialpose.pose.pose.orientation.z = init_position_[2];

initialpose.pose.pose.orientation.w = init_position_[3];

rclcpp::Rate pub_rate(10);

geometry_msgs::msg::PoseWithCovarianceStamped pose;

RCLCPP_DEBUG(this->get_logger(), "Publishing initial pose and waiting for valid /amcl_pose msg");

while (last_amcl_pose_ == pose) {

initialpose_pub_->publish(initialpose);

pub_rate.sleep();

}

Gist:

There is a vastly inaccurate heading computed to "tf_ship_pos" when robot is approximately at "tf_face_ship_pos". See log, Gazebo, and Rviz2 below:

| Log + Gazebo | Rviz2 |

|---|---|

|

|

Notes & questions:

- The

dirangle (the heading) should be almost zero as"tf_face_ship_pos"and"tf_ship_pos"are almost completely aligned, that is, the former "points at" the latter.

- Should

"tf_face_ship_pos"be used instead of"robot_base_footprint"as the origin frame? Can the accuracy of positioning be relied on?

Solution:

Do not subtract the robot's yaw from the result of atan2(y, x). The latter is already in the robot's frame if the parent/origin frame is robot_base_footprint.

Gist:

When commanded to back up from current position to a TF (situated generally behind the robot) the robot oscillates trying to achieve heading error below angular tolerance.

| Log + Gazebo | Rviz2 |

|---|---|

|

|

Notes:

- Robot steering is unintuitive because it is the opposite of what a car would do with a steering wheel. For example, if the steering wheel is rotated to the right, the car will turn right if going forward and also right if it's going backward. It would do circles in the same circular trajectory whether going forward or backward. The robot, if a negative angle is applied to the motion, it will turn to the right if it's going forward but it will turn left if it is going backward.

x > 0 x < 0 z < 0

z > 0

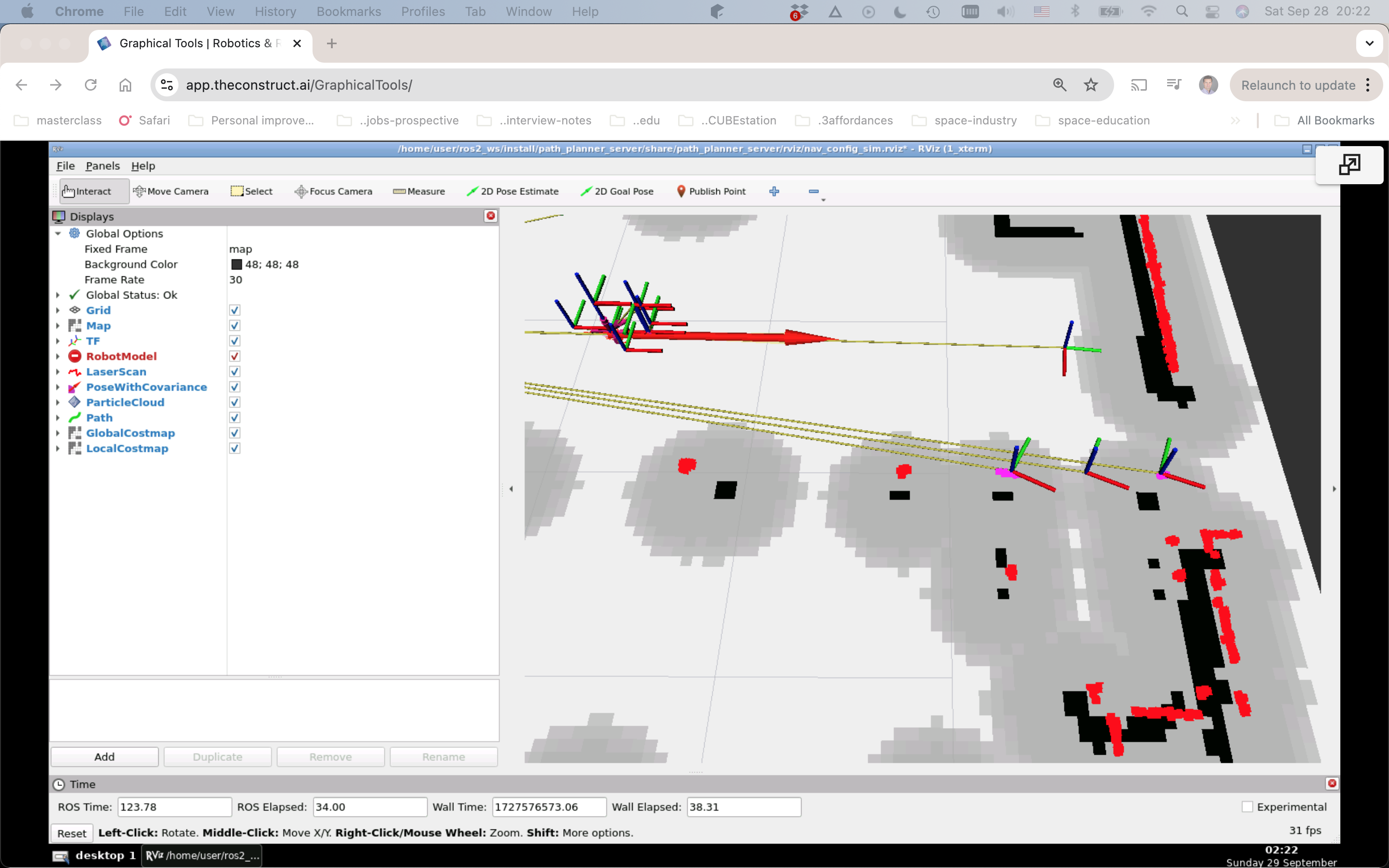

Gist:

With nav2 stack running, while robot is backing up (and twist.linear.x is negative), the robot moves backward in Gazebo but is shown to move forward in Rviz2.

| Log + Gazebo | Rviz2 |

|---|---|

|

|

Notes & questions:

- This is most probably due to the nav2 stack. Here are the messages from

global_costmap:[planner_server-5] [WARN] [1727041231.835360793] [global_costmap.global_costmap]: Sensor origin at (2.31, 2.80) is out of map bounds (-1.14, -4.30) to (6.64, 2.28). The costmap cannot raytrace for it. [planner_server-5] [WARN] [1727041232.834538499] [nav2_costmap_2d]: Robot is out of bounds of the costmap! [planner_server-5] [WARN] [1727041232.834584937] [global_costmap.global_costmap]: Sensor origin at (2.31, 2.80) is out of map bounds (-1.14, -4.30) to (6.64, 2.28). The costmap cannot raytrace for it. [planner_server-5] [WARN] [1727041233.834538888] [nav2_costmap_2d]: Robot is out of bounds of the costmap! [planner_server-5] [WARN] [1727041233.834587566] [global_costmap.global_costmap]: Sensor origin at (2.31, 2.80) is out of map bounds (-1.14, -4.30) to (6.64, 2.28). The costmap cannot raytrace for it. [planner_server-5] [WARN] [1727041234.834712621] [nav2_costmap_2d]: Robot is out of bounds of the costmap! [planner_server-5] [WARN] [1727041234.834831756] [global_costmap.global_costmap]: Sensor origin at (2.31, 2.80) is out of map bounds (-1.14, -4.30) to (6.64, 2.28). The costmap cannot raytrace for it. [planner_server-5] [WARN] [1727041231.835316157] [nav2_costmap_2d]: Robot is out of bounds of the costmap! - The log shows that the (negative) distance grows as if the robot is moving (forward and) farther away from the target frame.

- The laser scan contour remains faithful to the robot, that is, it stays correct to the robot as if it were moving backward. See below, in a simplified FORWARD then BACKWARD test:

| Log + Gazebo | Rviz2 |

|---|---|

|

|

Solution:

The hack of non-positive update_min_a and update_min_d parameters for AMCL does not seem to be true to physics and causes weird behaviors with localization. In the lab, the message "Negative eigenvalue found for position. Is the covariance matrix correct (positive semidefinite)?", along with the inability to set the initial pose through Rviz2, code, or command line showed unequivocally that this is not a realistic setting. In the simulator, it was the cause of the "forward" movement of the robot when it was actually simulated to move backward.

Gist:

The TF "tf_cart_front_midpoint" should have orientation that is normal to the line between the plates. This might be the yaw that is returned by solve_sas_triangle, but what is the angle that is passed to StaticTransformBroadcaster?

Gist:

The y is off. The x and yaw seem to be fine.

Approach:

- Publishing TFs relative to

"robot_front_laser_base_link".- New test,

tf_relative_to_laser.cpp. - New launch,

relative.launch.py. StaticTransformBroadcaster.- Try different x, y, and yaw.

- Determine where the new TFs appear relative to

"robot_front_laser_base_link"by labeling them to identify in Rviz2.

- New test,

- Continuously publishing

"tf_cart_front_midpoint".- New test,

cart_front_midpoint_test.cpp. - New launch,

midpoint.launch.py. TransformBroadcasterin a loop.- If reflective plates recognized, publish

"tf_cart_front_midpoint". Has to be in the right place and be fairly stable.

- New test,

Gist:

Published TFs which have to coincide with the incidnece contours in Rviz2 very rarely coincide and are usually quite a bit off.

| Log + Gazebo | Rviz2 |

|---|---|

|

|

Solution:

Compensate for 180-deg roll of "robot_front_laser_base_link".