This ESPHome component allows to use an ESPHome device (ESP8266 or ESP32) to control a Frisquet heating boiler, replacing the Eco Radio System remote thermostat.

The solution developed is applicable to all Frisquet boilers marketed until 2012 and fitted with the Eco Radio System module. More recent boilers equipped with the Visio module are not compatible because Frisquet has since implemented encryption in its communication protocol.

The Frisquet Boiler component appears as a Float Output device.

It is recommended to combine it with the Heating Curve Climate component also provided in this project. This Climate component will offer temperature control using an outdoor temperature sensor. If needed, it is also possible to use an other type of Climate component, such as the PID Climate.

Some parameters names and behaviour have changed in version 1.5. The parameters heat_factor and offset of the heat_curve_climatecomponent have been replaced by slope and shift. Those terms are more commonly used by boiler manufacturers.

Whilst slope provides the same functionnality as heat_factor, shift is slightly different. One way to define shift is to take the offset value you were previously using and substract your usual setpoint temperature (shift = offset - setpoint). Negative values are accepted.

The same changes are applicable to the component actions and component sensors.

This work is strongly inspired from:

- Décodage du signal Frisquet Eco Radio System (French)

- Decoding the wireless heating control Vaillant CalorMatic 340f

- frisquet-arduino

and from the discussions held in this thread:

The ESPHome replaces the original Eco Radio System HF receiver and is conneted to the boiler main board through a micro-fit 4 socket.

| ESP32 | Boiler Side | Pin number |

|---|---|---|

| GND | black wire | 1 |

| Pin 21 (configurable) | yellow wire | 2 |

| 5V | red wire (optional) | 3 |

Micro-fit 4 pin out:

Defined viewing direction for the connector pin out:

- Receptable - rear view

- Header - front view

Note: It has been observed that the current supplied by the boiler main board is not sufficent to power the ESP32.

The Frisquet ESPHome component consists of two components:

heat_curve_climatea custom Climate component that will control the boiler water setpoint based on target, current (internal) and outside temperatures and a heating curve formula.friquet_boilera custom Float Output component that will actually communicate with the Frisquet boiler.

They can be installed using the External Components feature of ESPHome.

The complete components folder must be copied into your esphome configuration folder and the YAML configuration file must show the following lines:

external_components:

- source: componentsWith this method, you don't have to copy the files onto your system. Instead, the configuration file will show the following lines:

external_components:

- source: github://philippemezzadri/frisquet-esphomeThe core component communicates with the boiler control board to send messages which contains a boiler identifier, heating mode and a setpoint water temperature as a ratio.

It drives the boiler by emitting the same signal that the remote does via VHF. The original receiver only transforms the radio signal into 5V TTL logic. The signal protocol is differential Manchester with bit-stuffing applied (whenever 5 ones are sent a stuffing 0 is appended). There is also a checksum.

You should ensure that your microcontroller will output a signal strong enough to drive the 5V logic. In many cases this will work, however you may use an optocoupler or a level shifter like this simple transistor schematic

The frisquet_boiler is then a Float Output component to send this signal to the boiler:

output:

- platform: frisquet_boiler

id: boiler_cmd

pin: 21

boiler_id: 03B9Configuration variables:

- id (Required, ID): The id to use for this output component.

- pin (Required, Pin): The pin number connected to the boiler.

- boiler_id (Required, string): The identifier of your boiler (see below).

- calibration_factor (Optional, float): Calibration factor of the boiler. Defaults to

1.9. - calibration_offset (Optional, float): Calibration offset of the boiler. Defaults to

-41. - All other options from Float Output.

If min_poweris set to a value that is not zero, it is important to set zero_means_zero to true. This can be safely ignored if min_power and max_power are kept at their default values.

The output value received by the component is any rational value between 0 and 1. Internaly, the output value is multiplied by 100 and rounded to an integer value because the Frisquet Boiler only accepts orders as integers between 0 and 100:

- 0 : boiler is stopped

- 01 - 100 : water heating

calibration_factor and calibration_offset are used by the internal sensor to calculate the equivalent water flow temperature out of the output value. The default values have been defined on a Frisquet Hydroconfort Evolution boiler. This is only used to return information to Home Assistant and has no impact on boiler control.

Note: The frisquet_boiler component will send commands to the boiler right after an update of the output value and then every 4 minutes. The component must receive regularly updates from the Climate component. To prevent overheating of the boiler, it will stop sending commands to the boiler if the output value is not updated during 15 minutes. In such case, the boiler will put itself in safe mode.

Important: the boiler ID that must be indicated in the YAML configuration file is a 4 hexa digit number required to allow your boiler to receive the messages from the ESP. There are many ways to find your ID:

- by connecting the radio receiver signal wire to an Arduino. See the frisquet-arduino project for more details;

- by listening with an RTL-SDR compatible receiver and the rtl_433 project;

- by opening your receiver and finding the number on the PCB (it is printed on the bottom left!).

It is also possible to assign any ID to the boiler using configuration mode (see below).

In addition, a Climate component is necessary to control the Frisquet Boiler Output.

It uses the target, ambiant and outside temperatures and a heating curve formula to calculate a target water temperature, and then calibrates it to the output value.

The PID Climate could be used but it does not provide smooth control and does not anticipate weather evolution.

It is otherwise recommended to use the Heating Curve Climate which adjusts the heating power according to the outdoor temperature.

climate:

- platform: heat_curve_climate

id: boiler_climate

name: "Chaudière Frisquet"

sensor: current_temperature

outdoor_sensor: outdoor_temperature

default_target_temperature: 19

output: boiler_cmd

control_parameters:

slope: 1.45

shift: 3

kp: 5

output_parameters:

minimum_output: 0.1

output_factor: 1.9

output_offset: -41Configuration variables:

- sensor (Required, ID): The sensor that is used to measure the current temperature.

- outdoor_sensor (Required, ID): The sensor that is used to measure the outside temperature.

- default_target_temperature (Required, float): The default target temperature (setpoint) for the control algorithm. This can be dynamically set in the frontend later.

- output (Required, ID): The ID of a float output that increases the current temperature.

- control_parameters (Optional): Control parameters of the controller (see below).

- alt_curve (Optional, boolean): Set to

trueto use an alternate heating curve. Defaults tofalse. - slope (Optional, float): The proportional term (slope) of the heating curve. Defaults to

1.5. - shift (Optional, float): The parallel shift term of the heating curve. Defaults to

0. - max_error (Optional, float): The regulation error above which the boiler stops (e.g. when the ambiant temperature is too high because of external heat inputs). Defaults to

1. - min_delta (Optional, float): The target/outdoor temperature difference below which the boiler stops. Defaults to

2. - kp (Optional, float): The factor for the proportional term of the heating curve. May be useful for accelerating convergence to target temperature. Defaults to

0. - ki (Optional, float): The factor for the integral term of the heating curve. May be useful if target temperature can't be reached. Use with caution when the house has a lot of thermal inertia. Defaults to

0.

- alt_curve (Optional, boolean): Set to

- output_parameters (Optional): Output parameters of the controller (see below).

- rounded (Optional, boolean): Forces rounding of the output value to two digits. Defaults to

false. - minimum_output (Optional, float): Output value below which output value is set to zero. Defaults to

0. - maximum_output (Optional, float): Output value above which output value won't go (cap). Defaults to

1. - heat_required_output (Optional, float): Minimum output value to be considered when the Heat Required switch is on. Defaults to

0.1. - output_factor (Optional, float): Calibration factor of the output. Defaults to

1. - output_offset (Optional, float): Calibration offset of the output. Defaults to

0.

- rounded (Optional, boolean): Forces rounding of the output value to two digits. Defaults to

- All other options from Climate

The boiler flow temperature is calculated from the outdoor temperature:

WATERTEMP = slope * DELTA + target temperature + shift

where :

WATERTEMPis the temperature setpoint for the water circulating in the heating circuit.DELTAis the temperature difference between the target and the outdoor,slopeandshiftare defined in the Climatecontrol_parameters.

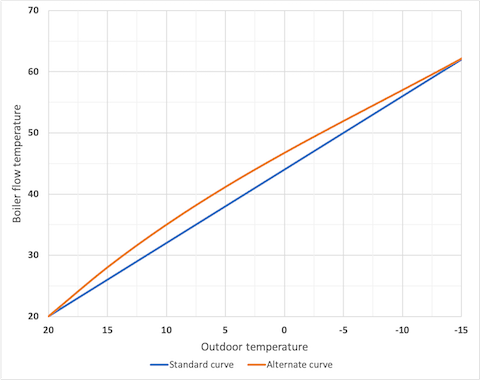

In this example, heating curves are given for an ambiant temperature (target) of 20°C with no shift. The shiftparameter allows you to move up and down the curves by a few degrees.

slope and shift strongly depend on the heat insulation of the house. Therefore slight adjustments may be necessary to find the best settings. Guidelines to do so can be found here (French).

In order to ease the fine tuning of those parameters, a service can be set in Home Assistant to change the parameters without restarting ESPHome (see below).

The following standard values for the slope may be used as a guide:

- 0.3 to 0.5 in a well insulated house with underfloor heating

- 1.0 to 1.2 for a well insulated house with radiators

- 1.4 to 1.6 for an older, detached building with radiators

If you don't know how to start, you can use the following values:

control_parameters:

slope: 1.5

shift: 0

kp: 2Alternate heating curve:

If you struggle in finding the good slopeand shift, you can try to set alt_curve to true. You can do it especially if you can't find settings that work for both cold winter and spring. The alternate heating curve is not linear like the standard curve but is polynomial and is designed to show a reduced slope for high delta between the outdoor and target temperatures.

In the above example, both curves have the same slope parameter.

If needed, proportionnal and integral terms can be added to the heating curve:

WATERTEMP = HEATING_CURVE_TEMP + ERROR* kp + INTEGRAL_TERM

where :

WATERTEMPis the temperature setpoint for the water circulating in the heating circuit.HEATING_CURVE_TEMPis the heating curve temperature calculated above.ERRORis the calculated error (target - current)INTEGRAL_TERMis the cumulative sum ofki*ERROR*dtdtis the time difference in seconds between two calculations.kpandkiare defined in the Climatecontrol_parameters.

Warning:

Setting a proportionnal factor kp can be useful to accelerate the convergence when the target temperature is changed. The value of kp should remain low to maintain the stability of the system and avoid overshoots.

However, setting an integral factor ki can be tricky to use and depends on many factors such as the house thermal inertia. We do not recommend to use it unless you know what you are doing.

In some instances, the boiler may go on idle mode because the ambiant temperature exceeds the maximum limit or if the outdoor temperature is too high. This is controlled by the max_error, min_delta and minimum_output settings.

If the above conditions disappear, the boiler will be allowed to restart only if the ambiant temperature goes below the target.

The boiler SETPOINT (integer in the [0 - 100] range) and the water flow temperature (WATERTEMP) are linked by the following formula:

SETPOINT = WATERTEMP * output_factor + output_offset

The actual value sent to the Output component is: RESULT= SETPOINT / 100

output_factor and output_offset are defined in the Climate output_parameters. They should match the calibration_factor and calibration_offset values of the boiler component if you are using both.

The following values are those of the Frisquet Hydromotrix and Hydroconfort boilers:

output_parameters:

output_factor: 1.9

output_offset: -41To get the Climate component working, two temperature sensors are required. They can be retrieved using homeassistant sensors:

sensor:

- platform: homeassistant

id: current_temperature

entity_id: sensor.living_room_temperature

unit_of_measurement: "°C"

filters:

- filter_out: nan

- heartbeat: 60s

- platform: homeassistant

id: outdoor_temperature

entity_id: sensor.outdoor_temperature

unit_of_measurement: "°C"

filters:

- filter_out: nan

- exponential_moving_average:

alpha: 0.3

send_every: 1

- heartbeat: 60sIf you are not using Home Assistant, you can use any local temperature sensor connected to the ESP or retrieve other sensor data using mqtt_subscribe sensors.

Note: Sensors should have a regular update interval as the heat curve update frequency is tied to the update interval of the sensors. We recommend putting a filter on the sensors to filter out the noise to ensure better stability of the output.

The original Eco Radio System remote provides two setup modes : configuration and testing. You can enter these modes by a long press on the up or down arrow buttons.

Those configuration modes are also available with the frisquet_boilercomponent. Control swiches to access these modes can be added with the following lines of code:

switch:

- platform: frisquet_boiler

pair:

name: "Configuration mode"

test:

name: "Test mode"When in configuration mode, press and hold the manual mode button (hand-shaped icon) on the boiler's control panel for 5 seconds; the manual control indicator blinks, indicating that it is receiving the radio transmission.

Release and press the button with the hand-shaped icon for 2 seconds to confirm the transmission.

You can then quit the configuration mode.

This procedure allows to associate an arbitrary ID to your boiler. This can be helpful if no remote control was previously associated with the boiler.

When in test mode, on the boiler's control panel, all the indicators are off except for the thermometer, which scrolls like a "caterpillar": the transmission is working efficiently.

On some occasions, external temperature conditions or high values of the Proportional and Integral factors may cause the boiler to enter idle mode (in accordance with max_error, min_delta and minimum_output settings). This can be undesirable as heat may be required by radiators in other rooms of the house.

To address this issue, the Heating Curve Climate platform provides a switch that will force the boiler to run at a minimum power level instead of shutting off completely.

This ensures that heat is still being supplied to the radiators and helps maintain a comfortable temperature throughout the house.

switch:

- platform: heat_curve_climate

name: "Heat Required"Configuration variables:

- name (Required, string): The name of the switch.

When the switch is on, the boiler will never go below the minimum power defined by the heat_required_output parameter.

Additionally, the Frisquet Boiler platform provides an optional sensor platform to monitor and give feedback from the Output component.

sensor:

- platform: frisquet_boiler

name: "Boiler Flow Temperature"

type: FLOWTEMPConfiguration variables:

- name (Required, string): The name of the sensor.

- type (Required, string): The value to monitor. One of

SETPOINT- The setpoint given the boiler (%).FLOWTEMP- The water temperature resulting from theSETPOINT.

If the boiler is off, the flow temperature is unavailable.

The Heating Curve Climate platform also provides an optional sensor platform to monitor and give feedback from the Climate component.

sensor:

- platform: heat_curve_climate

name: "Heating Curve Temperature"

type: WATERTEMPConfiguration variables:

- name (Required, string): The name of the sensor.

- type (Required, string): The value to monitor. One of

RESULT- The resulting value sent to the output component (float between 0 and 1).SETPOINT- The setpoint sent to the boiler (%, actually 100 *RESULT).WATERTEMP- The calculated heating water temperature.DELTA- The temperature difference between the target and the outdoor.ERROR- The calculated error (target - process_variable)PROPORTIONAL- The proportional term of the controller (ifkpis not 0).INTEGRAL- The integral term of the controller (ifkiis not 0).SLOPE- The current value ofslopeSHIFT- The current value ofshiftKP- The current value ofkpKI- The current value ofki

Those sensors may be useful to set up your heating curve control_parameters.

This action sets new values for the control parameters. This can be used to manually tune the controller. Make sure to update the values you want on the YAML file! They will reset on the next reboot.

on_...:

then:

- climate.heat_curve.set_control_parameters:

id: boiler_climate

slope: 1.2

shift: 1

kp: 0Configuration variables:

- id (Required, ID): ID of the Heating Curve Climate.

- heat_factor (Required, float): The proportional term (slope) of the heating curve.

- offset (Required, float): The offset term of the heating curve.

- kp (Optional, float): The factor for the proportional term of the controller. Defaults to 0.

- ki (Optional, float): The factor for the integral term of the controller. Defaults to 0.

This action resets the integral term of the PID controller to 0. This might be necessary under certain conditions to avoid the control loop to overshoot (or undershoot) a target.

on_...:

# Basic

- climate.heat_curve.reset_integral_term: boiler_climateConfiguration variables:

- id (Required, ID): ID of the Heating Curve Climate being reset.

This action sets the boiler operating mode. This parameter is actually included in the frames sent to the boiler but I haven't seen any significant effect of the setting.

on_...:

then:

- output.set_mode:

id: boiler_cmd

mode: 3Configuration variables:

- id (Required, ID): ID of the Frisquet Boiler Output.

- mode (Required, int): operating mode (0 = eco / 3 = confort / 4 = away)

The frisquet_boiler Output component also inherits actions from Float Output and in particular output.set_level.

This action sets the float output to the given level when executed. This can be usefull to set the boiler output if it is not connected to a Climate component.

on_...:

then:

- boiler.set_level:

id: boiler_cmd

level: 50%Configuration variables:

- id (Required, ID): ID of the Frisquet Boiler Output.

- level (Required, percentage): output level

The Heating Curve Climate component automatically appears in Home Assistant as a Climate integration.

Also, when using the native API with Home Assistant, it is also possible to get data from Home Assistant to ESPHome with user-defined services. When you declare services in your ESPHome YAML file, they will automatically show up in Home Assistant and you can call them directly.

This way it is possible to call the actions provided by the Boiler Output and Heating Curve Climate components:

# Example configuration entry

api:

actions:

- action: set_boiler_setpoint

variables:

setpoint: int

then:

- output.set_level:

id: boiler_cmd

level: !lambda 'return setpoint / 100.0;'

- action: set_boiler_mode

variables:

mode: int

then:

- boiler.set_mode:

id: boiler_cmd

mode: !lambda 'return mode;'

- action: set_control_parameters

variables:

slope: float

shift: float

kp: float

then:

- climate.heat_curve.set_control_parameters:

id: boiler_climate

slope: !lambda 'return slope;'

shift: !lambda 'return shift;'

kp: !lambda 'return kp;'

- climate.heat_curve.reset_integral_term: boiler_climateThose lines in the YAML file will expose three actions in Home Assistant that can be called with the following lines (provided that the ESP device name is myFrisquetBoiler):

action: esphome.myFrisquetBoiler_set_control_parameters

data:

slope: 1.2

shift: 3

kp: 0action: esphome.myFrisquetBoiler_set_boiler_setpoint

data:

level: 50action: esphome.myFrisquetBoiler_set_boiler_mode

data:

mode: 3Those are only examples. Any kind of service can be defined to suit your needs.

The boiler.yaml file includes all options described above. To use it, you need to customize all sensors IDs and names. If you are using Dallas temperature sensor, you need to enter their proper addresses. If not, you have to delete the corresponding lines.

The automations/boiler.yaml file is to be used in Home Assistant. It includes input_number and automation definitions that allow you to easily manage the control_parameters of the ESP. IDs and entity names should be changed before use to suit your own configuration.

The proposed automations allows you to modifiy the output_parameters from the Home Assistant UI and to restore them anytime the ESP reboots.

One way of using this file is to copy it in a folder named packagesof your Home Assistant config folder and then add the following in your configuration.yaml file:

homeassistant:

packages: !include_dir_named packages